Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

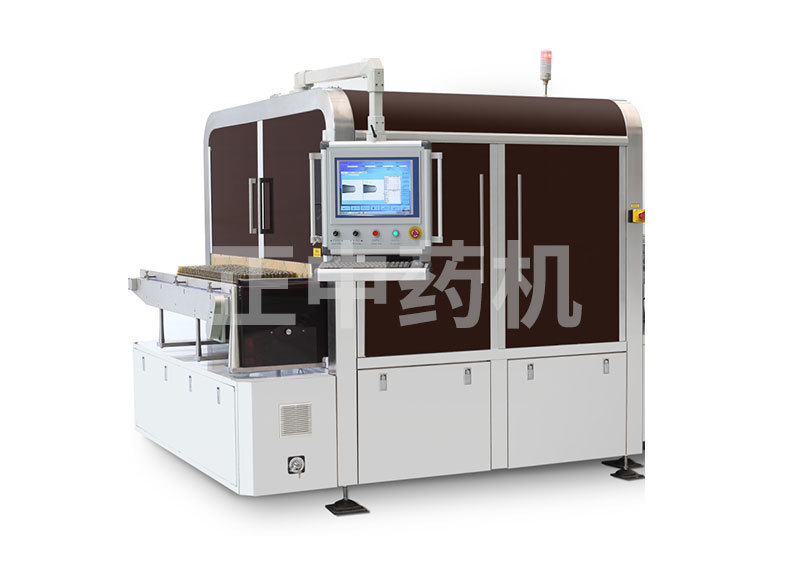

JYWD120X Automatic Foreign Object Detection Machine for Flexible Bags

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Soft bag automatic electronic microporous leak detector

Details

Main Uses

The equipment is primarily designed for detecting visible foreign objects and visual defects in water-injection drugs packaged in transparent soft bags. Detection items for foreign objects include glass shards, hair, white particles, and more, while visual inspection items cover aspects such as rubber stoppers and external shape defects.

How it works

Utilize machine vision principles to detect visible foreign objects and assess appearance.

Visible foreign object detection: The product to be inspected rotates driven by the rotating disk. When the disk stops, the liquid medicine continues moving due to inertia, thereby setting in motion any foreign objects within the liquid. At this moment, the machine vision system captures multiple images continuously, analyzing and determining whether the product meets quality standards.

Appearance defect detection: After the soft bag is picked up by a robotic arm and placed on the platform, a camera captures the bag's shape and the position of the rubber stopper. The images are then processed to analyze whether any defects are present.

Process Flow

Product awaiting inspection → Bottle-feeding conveyor belt → Robotic arm for material sorting → External and rubber stopper inspection → Bagging mechanism with gripper → Foreign object detection → Qualified and non-qualified products discharged into separate bags

Main Technical Parameters

Production capacity: 120 × (1 ±10%) bags per minute

Applicable specifications: 50–250 mL

Voltage: 380V; 50Hz

Total power: 15 kW

Working height: 900 ± 50 mm

External dimensions: 5000 × 2400 × 2000 (mm) (L × W × H)

Net weight: Approximately 4,500 kg

Key Features

- Fully independently developed, it employs a patented rotary-bagging method that ensures complete movement of foreign objects, effectively preventing missed detections; the entire machine boasts entirely independent intellectual property rights.

- Using multiple SCARA robots to handle bagging tasks, this solution features a compact structure, making it ideal for installation in pharmaceutical factory environments.

- Suitable for multiple specifications—no need to replace specification parts.

- Utilizing ultra-high-speed, high-resolution industrial cameras for precise detection.

- Utilize a wireless operation screen, allowing you to control the device from any location around it.

- All key electrical components, bearings, and more are sourced from leading domestic and international brands.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

The equipment is primarily designed for detecting visible foreign objects and visual defects in water-injection drugs packaged in transparent soft bags. Detection items for foreign objects include glass shards, hair, white particles, and more, while visual inspection items cover aspects such as rubber stoppers and external shape defects.

How it works

Utilize machine vision principles to detect visible foreign objects and assess appearance.

Visible foreign object detection: The product to be inspected rotates driven by the rotating disk. When the disk stops, the liquid medicine continues moving due to inertia, thereby setting in motion any foreign objects within the liquid. At this moment, the machine vision system captures multiple images continuously, analyzing and determining whether the product meets quality standards.

Appearance defect detection: After the soft bag is picked up by a robotic arm and placed on the platform, a camera captures the bag's shape and the position of the rubber stopper. The images are then processed to analyze whether any defects are present.

Process Flow

Product awaiting inspection → Bottle-feeding conveyor belt → Robotic arm for material sorting → External and rubber stopper inspection → Bagging mechanism with gripper → Foreign object detection → Qualified and non-qualified products discharged into separate bags

Main Technical Parameters

Production capacity: 120 × (1 ±10%) bags per minute

Applicable specifications: 50–250 mL

Voltage: 380V; 50Hz

Total power: 15 kW

Working height: 900 ± 50 mm

External dimensions: 5000 × 2400 × 2000 (mm) (L × W × H)

Net weight: Approximately 4,500 kg

Key Features

- Fully independently developed, it employs a patented rotary-bagging method that ensures complete movement of foreign objects, effectively preventing missed detections; the entire machine boasts entirely independent intellectual property rights.

- Using multiple SCARA robots to handle bagging tasks, this solution features a compact structure, making it ideal for installation in pharmaceutical factory environments.

- Suitable for multiple specifications—no need to replace specification parts.

- Utilizing ultra-high-speed, high-resolution industrial cameras for precise detection.

- Utilize a wireless operation screen, allowing you to control the device from any location around it.

- All key electrical components, bearings, and more are sourced from leading domestic and international brands.

Previous Page

Related Products

Inquiry