Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

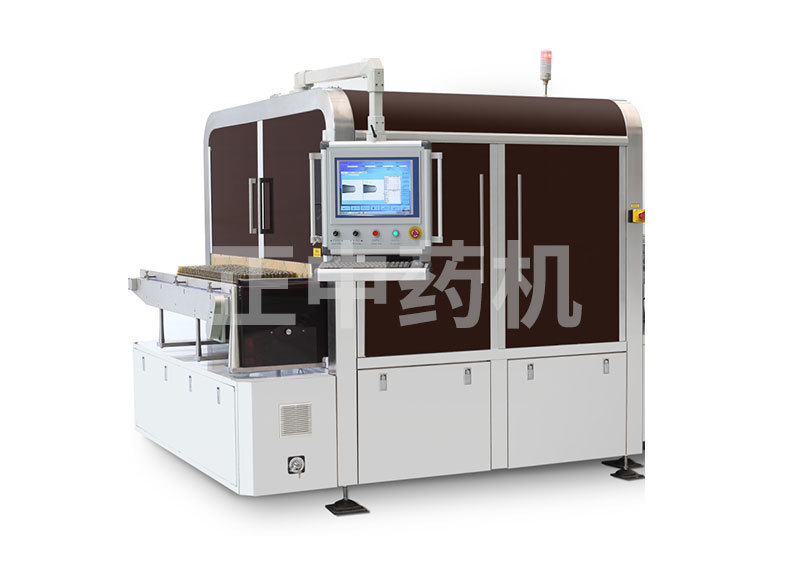

RJL7200/1000 Soft-Bag Electronic Leak Detector

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Soft bag automatic electronic microporous leak detector

Details

Main Uses

Primarily used for sealing integrity testing of non-PVC infusion soft bags; it provides full-coverage inspection of the bag's welded areas (including connectors and bag body) as well as the bag's surface.

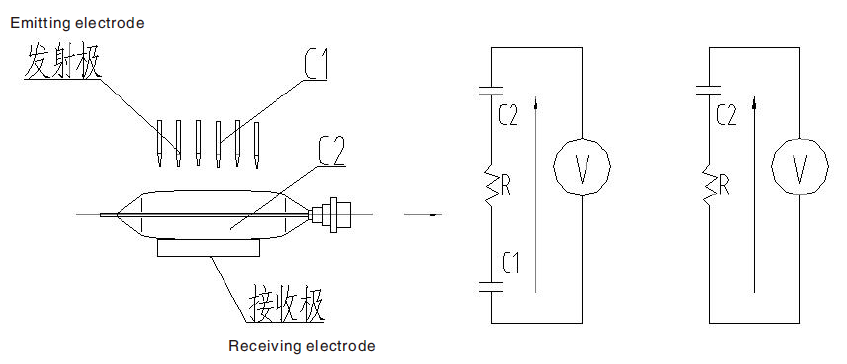

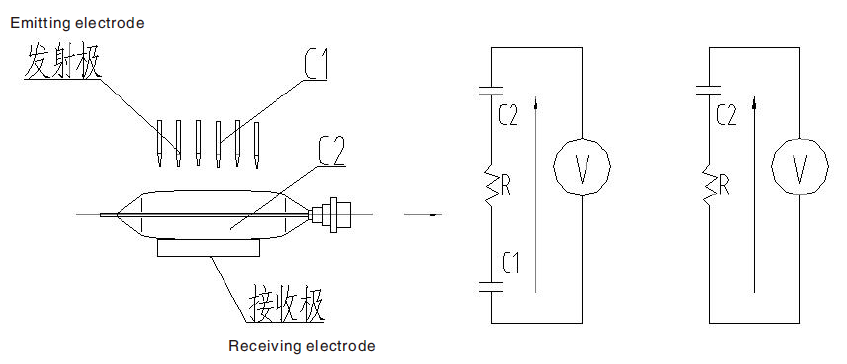

Detection Principle

V is a high-frequency, high-voltage detection power supply, with its two ends connected respectively to the emitter and receiver electrodes. C1 and C2 represent the capacitance values between the electrodes and the capacitors (since the insulating soft-bag membrane prevents direct contact between the electrodes and the medicinal solution, capacitance is thus generated). R denotes the resistance of the medicinal solution. When the soft bag remains intact without leakage, an induced microcurrent I1 is produced. However, if the soft bag develops a leak, the capacitance between the bag membrane and the electrodes disappears entirely, causing the capacitive reactance to drop to zero. This results in a significantly larger microcurrent I2 flowing through the circuit. By comparing the magnitudes of these microcurrents, we can determine whether the soft bag has leaked or not.

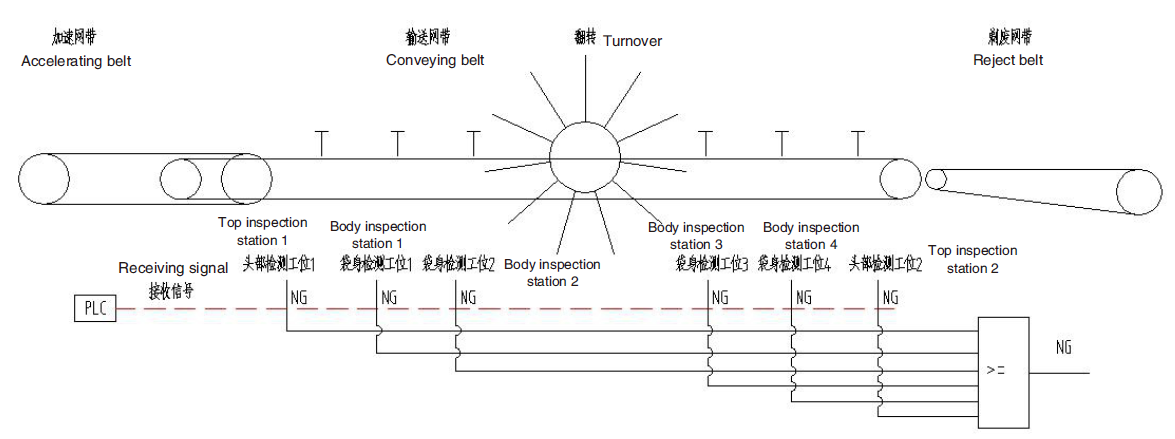

Process Flow

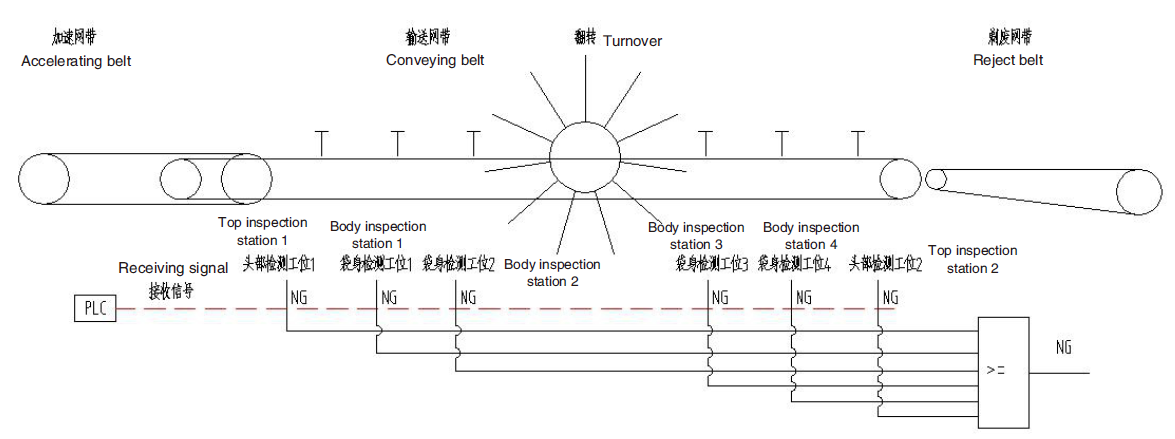

Pending products → Accelerated conveyor belt into bags → Head detection 1 → Bag body detection 1 → Bag body detection 2 → Turning over → Bag body detection 3 → Bag body detection 4 → Head detection 2 → Automatic separation of合格品 (qualified products) and 不合格品 (non-qualified products)

Main Technical Parameters

Applicable Scope: 50–1000 ml Non-PVC Soft Bags

Testing Item: Sealing Integrity Test

Detection speed: 120 × (1 ± 5%) bags per minute

Detection accuracy: ≥0.1 μm

Capacitance: 5 kW

Voltage: AC380V, 50Hz

Workbench height: (850 ± 40) mm

External dimensions: 4050 × 1040 × 1500 mm (L × W × H)

Net weight: Approximately 1500 kg

Key Features

- Employing the high-voltage discharge detection principle, the energy applied to the product is low and the duration is brief, eliminating any risk of secondary contamination to the drug.

- Using flexible electrodes, it can detect ultra-fine pores and cracks larger than 0.1 micrometer, with high repeatability in detection accuracy.

- Our unique flipping technology enables inspection on both sides of the bag, achieving all-around, blind-spot-free detection.

- Replacing a small number of specification parts allows for testing across various product volumes, while the test voltage and frequency can be easily adjusted according to different products.

- Utilizing servo motor drive and industrial PC control, the system features a user-friendly touch-screen interface. All inspection data can be saved, uploaded, and printed.

- The conveying mechanism and detection unit are positioned above the workbench panel, isolated from the electrical control section, featuring a compact structure and convenient maintenance.

- Equipped with door-activated shutdown, ozone catalysis, and electromagnetic shielding devices to protect the operator's personal safety.

- It features multiple fault alarms and protection functions; when improper operations occur, the machine will automatically trigger an alarm or shut down while displaying the cause of the malfunction.

- It can be produced offline or operated in a networked setup.

- Possessing fully independent intellectual property rights, with multiple invention and utility model patents.

- And it has passed CE certification.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

Primarily used for sealing integrity testing of non-PVC infusion soft bags; it provides full-coverage inspection of the bag's welded areas (including connectors and bag body) as well as the bag's surface.

Detection Principle

V is a high-frequency, high-voltage detection power supply, with its two ends connected respectively to the emitter and receiver electrodes. C1 and C2 represent the capacitance values between the electrodes and the capacitors (since the insulating soft-bag membrane prevents direct contact between the electrodes and the medicinal solution, capacitance is thus generated). R denotes the resistance of the medicinal solution. When the soft bag remains intact without leakage, an induced microcurrent I1 is produced. However, if the soft bag develops a leak, the capacitance between the bag membrane and the electrodes disappears entirely, causing the capacitive reactance to drop to zero. This results in a significantly larger microcurrent I2 flowing through the circuit. By comparing the magnitudes of these microcurrents, we can determine whether the soft bag has leaked or not.

Process Flow

Pending products → Accelerated conveyor belt into bags → Head detection 1 → Bag body detection 1 → Bag body detection 2 → Turning over → Bag body detection 3 → Bag body detection 4 → Head detection 2 → Automatic separation of合格品 (qualified products) and 不合格品 (non-qualified products)

Main Technical Parameters

Applicable Scope: 50–1000 ml Non-PVC Soft Bags

Testing Item: Sealing Integrity Test

Detection speed: 120 × (1 ± 5%) bags per minute

Detection accuracy: ≥0.1 μm

Capacitance: 5 kW

Voltage: AC380V, 50Hz

Workbench height: (850 ± 40) mm

External dimensions: 4050 × 1040 × 1500 mm (L × W × H)

Net weight: Approximately 1500 kg

Key Features

- Employing the high-voltage discharge detection principle, the energy applied to the product is low and the duration is brief, eliminating any risk of secondary contamination to the drug.

- Using flexible electrodes, it can detect ultra-fine pores and cracks larger than 0.1 micrometer, with high repeatability in detection accuracy.

- Our unique flipping technology enables inspection on both sides of the bag, achieving all-around, blind-spot-free detection.

- Replacing a small number of specification parts allows for testing across various product volumes, while the test voltage and frequency can be easily adjusted according to different products.

- Utilizing servo motor drive and industrial PC control, the system features a user-friendly touch-screen interface. All inspection data can be saved, uploaded, and printed.

- The conveying mechanism and detection unit are positioned above the workbench panel, isolated from the electrical control section, featuring a compact structure and convenient maintenance.

- Equipped with door-activated shutdown, ozone catalysis, and electromagnetic shielding devices to protect the operator's personal safety.

- It features multiple fault alarms and protection functions; when improper operations occur, the machine will automatically trigger an alarm or shut down while displaying the cause of the malfunction.

- It can be produced offline or operated in a networked setup.

- Possessing fully independent intellectual property rights, with multiple invention and utility model patents.

- And it has passed CE certification.

Previous Page

Previous Page

Related Products

Inquiry