Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

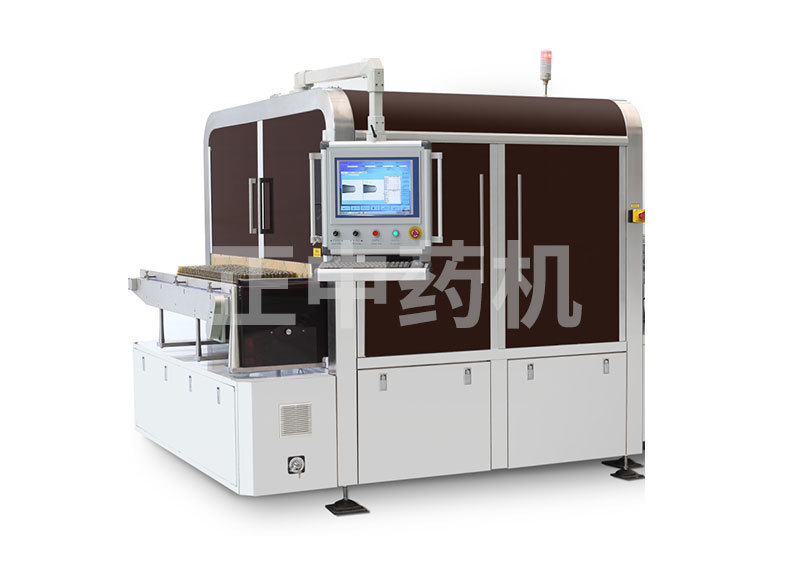

JAZ20/600X Oral Liquid Automatic Foreign Object Inspection Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Automatic inspection machine for oral liquid foreign objects

Details

Main Uses

Primarily used for detecting visible foreign objects (including glass shards, metal particles, fibers, hair, white lumps, white spots, etc.) in oral liquids, as well as inspecting the capping quality and liquid level.

How it works

This machine utilizes the principle of machine vision: after the product being inspected rotates at high speed, it momentarily comes to a stop. An industrial camera then continuously captures images, which are analyzed by a computer system to determine whether the product meets quality standards—and automatically sorts out合格品 (qualified products) from 不合格品 (defective products).

Process Flow

Product awaiting inspection → Bottle feeding → Bottle-feeding indexing wheel (for inspecting large glass containers) → Bottle pressing and clamping → Bottle spinning → Braking → Image capture → Image processing and analysis → Bottle ejection → Separation of合格品 (qualified products) and 不合格品 (non-qualified products).

Main Technical Parameters

Applicable Scope: 5-20ml Glass Bottles for Oral Liquids

Testing items: Visible foreign objects (glass shards, metal particles, fibers, hair, white flakes, white spots, etc.), cap-closing quality, and liquid level.

Detection speed: 600 bottles per minute

Detection accuracy: 40 μm (adjustable)

Capacitance: 9.5 kW

Voltage: 380V, 50Hz

Workbench height: 925mm

External dimensions: 2310mm × 2108mm × 1880mm (Length × Width × Height)

Net weight: Approximately 3,500 kg

Key Features

① The entire machine features a brand-new, patented design with an innovative and more rational structure, ensuring stable operation and convenient maintenance.

② The entire machine features full servo drive, ensuring more precise transmission and making operation adjustments even more convenient.

③ Utilizes a universally recognized top-and-bottom clamping bottle-holding method, coupled with a patented rotary bottle-driving mechanism. This ensures both the stability of bottle clamping and consistent rotation speed, while also simplifying cleaning and maintenance procedures.

④ There is a specially designed large glass inspection station.

⑤ The bottle-rotating servo system and the detection device are both mounted on the panel, which completely isolates the underlying transmission mechanism. This design ensures convenient and straightforward operation and maintenance, making it easy to clean without causing any contamination to the equipment.

⑥ All specification parts feature a quick-release design for faster replacement of components.

⑦ Utilizing a screw conveyor for bottle feeding ensures seamless coordination when linking the machine to upstream or downstream processes.

⑧ Equipped with multiple fault alarms and protection features, the machine will sound an alarm or shut down automatically—and display the cause of the malfunction—when a fault occurs or if operations are performed improperly.

⑨ All test data can be saved, uploaded, and printed.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

Primarily used for detecting visible foreign objects (including glass shards, metal particles, fibers, hair, white lumps, white spots, etc.) in oral liquids, as well as inspecting the capping quality and liquid level.

How it works

This machine utilizes the principle of machine vision: after the product being inspected rotates at high speed, it momentarily comes to a stop. An industrial camera then continuously captures images, which are analyzed by a computer system to determine whether the product meets quality standards—and automatically sorts out合格品 (qualified products) from 不合格品 (defective products).

Process Flow

Product awaiting inspection → Bottle feeding → Bottle-feeding indexing wheel (for inspecting large glass containers) → Bottle pressing and clamping → Bottle spinning → Braking → Image capture → Image processing and analysis → Bottle ejection → Separation of合格品 (qualified products) and 不合格品 (non-qualified products).

Main Technical Parameters

Applicable Scope: 5-20ml Glass Bottles for Oral Liquids

Testing items: Visible foreign objects (glass shards, metal particles, fibers, hair, white flakes, white spots, etc.), cap-closing quality, and liquid level.

Detection speed: 600 bottles per minute

Detection accuracy: 40 μm (adjustable)

Capacitance: 9.5 kW

Voltage: 380V, 50Hz

Workbench height: 925mm

External dimensions: 2310mm × 2108mm × 1880mm (Length × Width × Height)

Net weight: Approximately 3,500 kg

Key Features

① The entire machine features a brand-new, patented design with an innovative and more rational structure, ensuring stable operation and convenient maintenance.

② The entire machine features full servo drive, ensuring more precise transmission and making operation adjustments even more convenient.

③ Utilizes a universally recognized top-and-bottom clamping bottle-holding method, coupled with a patented rotary bottle-driving mechanism. This ensures both the stability of bottle clamping and consistent rotation speed, while also simplifying cleaning and maintenance procedures.

④ There is a specially designed large glass inspection station.

⑤ The bottle-rotating servo system and the detection device are both mounted on the panel, which completely isolates the underlying transmission mechanism. This design ensures convenient and straightforward operation and maintenance, making it easy to clean without causing any contamination to the equipment.

⑥ All specification parts feature a quick-release design for faster replacement of components.

⑦ Utilizing a screw conveyor for bottle feeding ensures seamless coordination when linking the machine to upstream or downstream processes.

⑧ Equipped with multiple fault alarms and protection features, the machine will sound an alarm or shut down automatically—and display the cause of the malfunction—when a fault occurs or if operations are performed improperly.

⑨ All test data can be saved, uploaded, and printed.

Related Products

Inquiry