Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

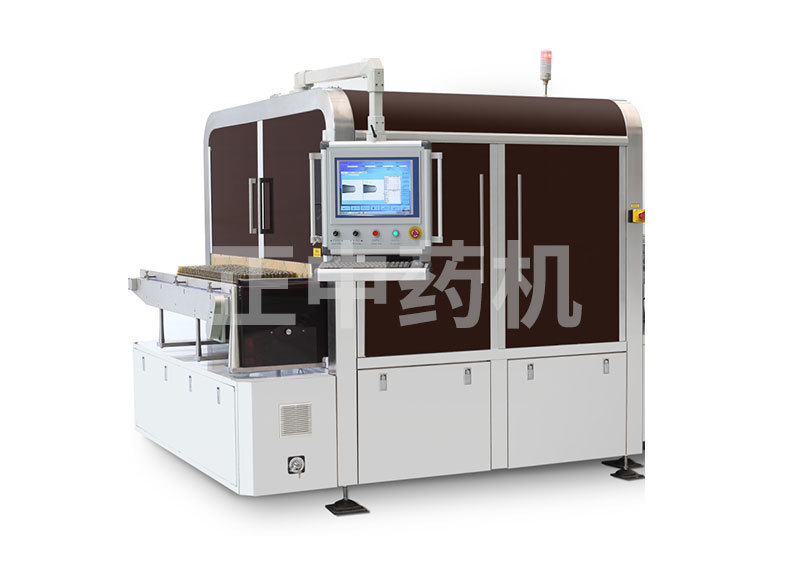

ZJL250 Vacuum Decay Leak Detector

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Vacuum decay leak detector

Keyword

Details

Structural Principle

This machine primarily consists of components such as the bottle-in mechanism, rotary inspection area, bottle-out mechanism, bottle-dividing unit, frame, and control operating system.

The wine bottle to be tested is conveyed along a track, where it is separated into individual bottles by an infeed screw conveyor before being fed into the indexing wheel. From there, the bottles are transferred to the test chamber located in the rotary inspection area. Once the test chamber is sealed, a vacuum is drawn inside. This creates an internal-external pressure differential within the packaging container, causing any internal gases to escape through even the tiniest leaks and enter the test chamber. A differential pressure sensor connected to the test chamber then detects the resulting change in pressure. By comparing this pressure reading with the pressure measured on the other end of the sensor—connected to a perfectly sealed reference container—the system determines whether the tested packaging container has a leak. Finally, after passing through the rotary inspection area, the tested containers are moved to the bottle-out feed wheel, where they are further sorted into合格品 (qualified products) and 不合格品 (defective products) by a rejection mechanism equipped with an outfeed screw conveyor.

Work Flow

Its workflow can be summarized as follows: container to be tested → bottle-in-feed track → bottle-in-feed screw conveyor → bottle-in-feed indexing wheel → rotary inspection station → vacuum decay leak detection → bottle-out-feed indexing wheel → separator that sorts合格品 (qualified products) and 不合格品 (unqualified products) based on computer instructions → finally, qualified and unqualified products are directed into their respective bottle-out-feed tracks.

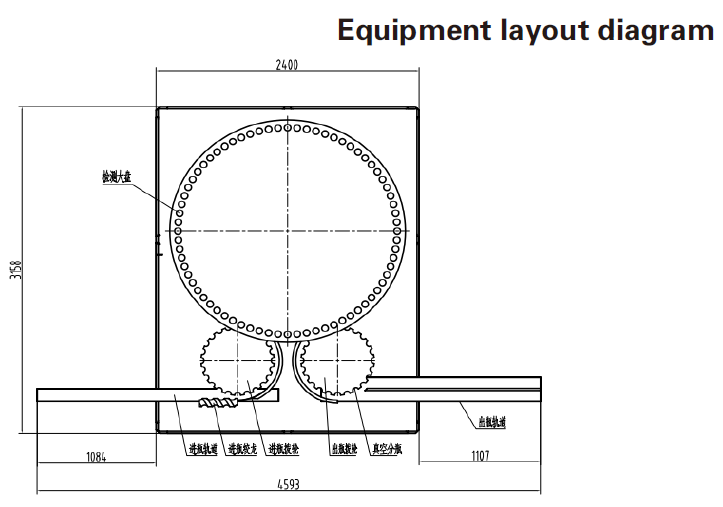

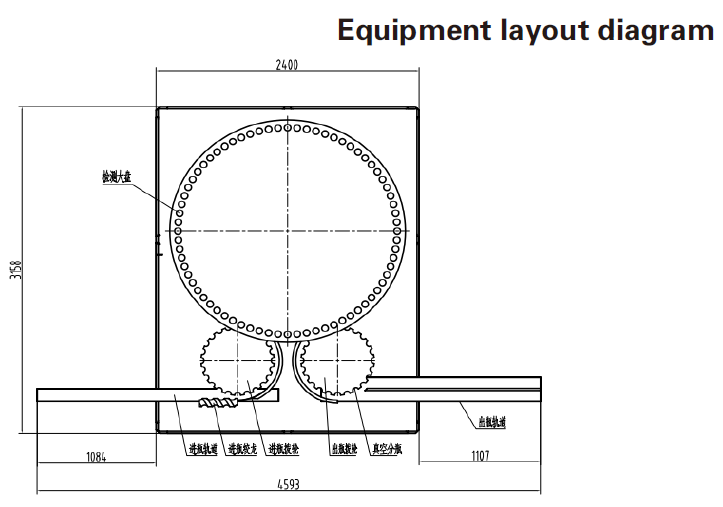

Equipment Layout Diagram

Key Features

- Employing differential pressure detection, the system offers high detection accuracy.

- Key components are manufactured using CNC precision machining, while major purchased parts come from well-known brands, ensuring stable and reliable equipment operation.

- Standard components feature a quick-loading and unloading design, significantly reducing the time required for specification changes.

- It features fault alarm and fault display functions; when a malfunction occurs or improper operation takes place, the equipment will either sound an alarm or shut down. It also includes a door-opening stop protection function.

- Features Level 3 permission capabilities.

- Equipped with a UPS power supply to prevent data loss caused by unexpected power outages.

- Equipped with audit trail functionality, it records device operations and parameter modifications.

- Check data to automatically generate reports, which can be queried, exported, or directly printed.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Structural Principle

This machine primarily consists of components such as the bottle-in mechanism, rotary inspection area, bottle-out mechanism, bottle-dividing unit, frame, and control operating system.

The wine bottle to be tested is conveyed along a track, where it is separated into individual bottles by an infeed screw conveyor before being fed into the indexing wheel. From there, the bottles are transferred to the test chamber located in the rotary inspection area. Once the test chamber is sealed, a vacuum is drawn inside. This creates an internal-external pressure differential within the packaging container, causing any internal gases to escape through even the tiniest leaks and enter the test chamber. A differential pressure sensor connected to the test chamber then detects the resulting change in pressure. By comparing this pressure reading with the pressure measured on the other end of the sensor—connected to a perfectly sealed reference container—the system determines whether the tested packaging container has a leak. Finally, after passing through the rotary inspection area, the tested containers are moved to the bottle-out feed wheel, where they are further sorted into合格品 (qualified products) and 不合格品 (defective products) by a rejection mechanism equipped with an outfeed screw conveyor.

Work Flow

Its workflow can be summarized as follows: container to be tested → bottle-in-feed track → bottle-in-feed screw conveyor → bottle-in-feed indexing wheel → rotary inspection station → vacuum decay leak detection → bottle-out-feed indexing wheel → separator that sorts合格品 (qualified products) and 不合格品 (unqualified products) based on computer instructions → finally, qualified and unqualified products are directed into their respective bottle-out-feed tracks.

Equipment Layout Diagram

Key Features

- Employing differential pressure detection, the system offers high detection accuracy.

- Key components are manufactured using CNC precision machining, while major purchased parts come from well-known brands, ensuring stable and reliable equipment operation.

- Standard components feature a quick-loading and unloading design, significantly reducing the time required for specification changes.

- It features fault alarm and fault display functions; when a malfunction occurs or improper operation takes place, the equipment will either sound an alarm or shut down. It also includes a door-opening stop protection function.

- Features Level 3 permission capabilities.

- Equipped with a UPS power supply to prevent data loss caused by unexpected power outages.

- Equipped with audit trail functionality, it records device operations and parameter modifications.

- Check data to automatically generate reports, which can be queried, exported, or directly printed.

Previous Page

Next Page

Previous Page

Next Page

Related Products

Inquiry