Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

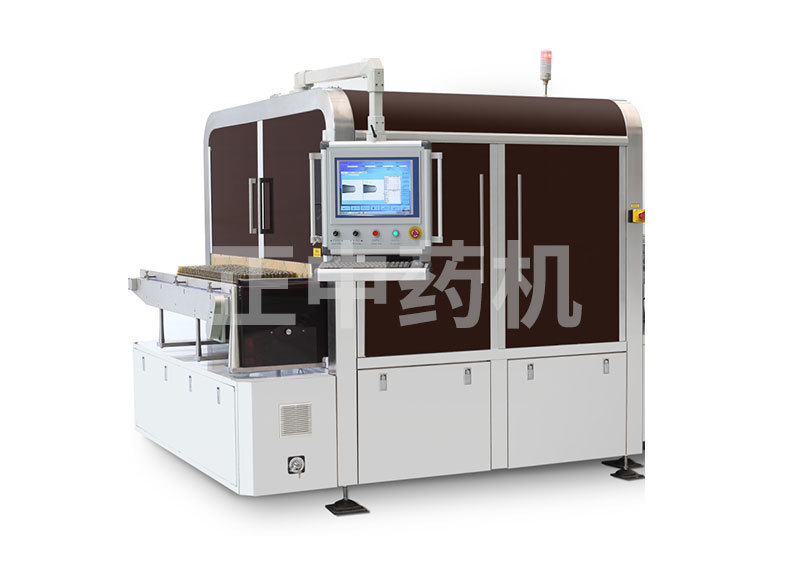

RJL3000 Soft Bag Automatic Electronic Micropore Leak Detection Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Soft bag automatic electronic microporous leak detector

Details

Main Uses

Primarily used for leak detection in flexible-bag intravenous solutions (hereafter referred to as "soft bags"). This includes detecting leaks at defects such as micro-pores in the soft bag (larger than 0.1 μm), compression seals along the bag body, welds at the bag opening, and welds at the bag tubing connection points.

How it works

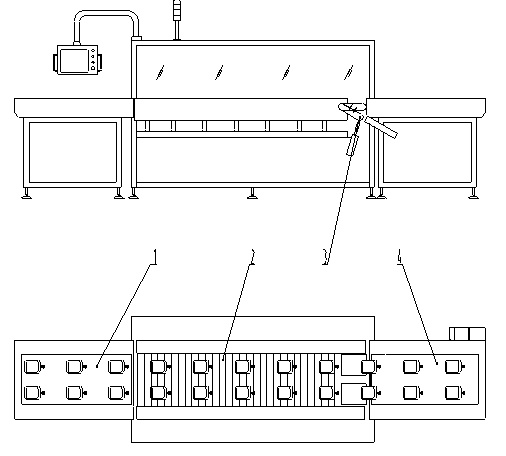

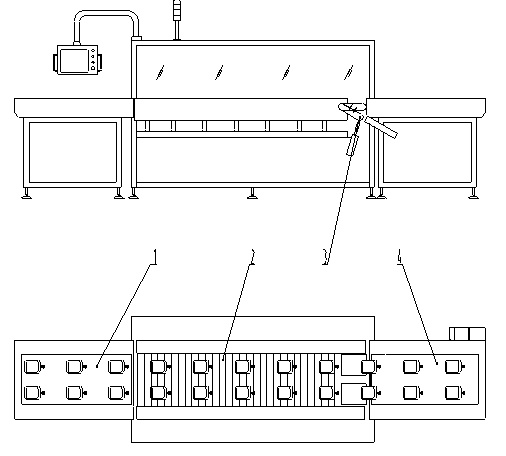

The soft bags to be inspected are evenly spaced into two rows as they move along the conveyor belt (1), then conveyed into the inspection channel (2). The inspection channel uses roller conveyance and is divided into two separate inspection areas—front and back—each equipped with four inspection stations. At each station, the position for detection can be adjusted as needed, ensuring that every part of the soft bag is thoroughly checked for leaks. Non-conforming products are automatically rejected by the waste-disposal mechanism (3), while合格品 are discharged from the conveyor belt (4).

Detection Principle

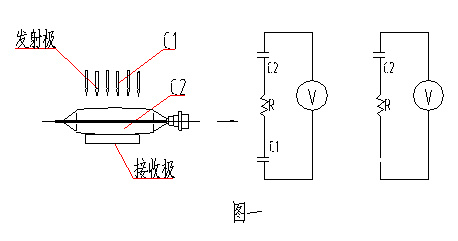

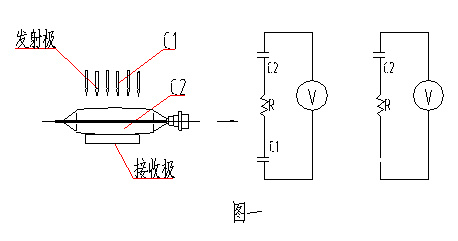

V is a high-frequency, high-voltage detection power supply, with its two ends connected respectively to the emitter and receiver electrodes. C1 and C2 represent the capacitance values between the electrodes and the capacitors (since the insulating soft-bag membrane prevents direct contact between the electrodes and the medicinal solution, capacitance is thus generated). R denotes the resistance of the medicinal solution. When the soft bag remains intact without leakage, a minute induced current I1 is produced. However, if the soft bag develops a leak, the capacitance between the bag membrane and the electrodes disappears, causing the capacitive reactance to drop to zero. As a result, the circuit generates a significantly larger microcurrent I2. By simply comparing the magnitudes of these microcurrents, it becomes possible to determine whether the soft bag has leaked or not.

Main Technical Parameters

1. Production Capacity: 2,500–3,000 bags/hour

2. Capacitance: 2.6 kW, 380V 50Hz

3. Power output range: 10kV–45kV

4. Frequency output range: 500Hz to 50kHz

5. Power Channel Count: Outputs multiple high-frequency, high-voltage power channels

6. Compressed air: 0.1–1.0 MPa

7. Weight: Approximately 1200 kg

8. Overall dimensions: 4489 × 1200 × 1500 mm (L × W × H)

Main advantages

1. There is no risk of secondary contamination from the drug. By eliminating the use of liquid substances like dye solutions, we prevent issues such as contamination of the medication.

2. Capable of detecting ultra-fine pores and cracks (above 0.1 micrometer), offering leak detection accuracy that traditional methods lack.

3. Fully automatic, full-scale online leak testing performed bag by bag. It can operate either as a standalone unit or be integrated into a connected production line, enabling a complete set of automated assembly-line operations.

4. Due to the low energy and short duration of the applied load, there are no side effects on the liquid medicine inside the product; this enables non-destructive inspection of soft bags.

5. A single device can be used for leak testing of soft bags with various fill volume specifications.

6. Special requirements. The critical areas of soft bags can be inspected according to the needs of different users.

7. The entire machine features a compact structure and an aesthetically pleasing design. Its user-friendly touchscreen interface offers powerful functions such as control, display, and data acquisition and storage.

8. Voltage and frequency can be adjusted according to different products.

9. Provide validation documents and a validation plan

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

Primarily used for leak detection in flexible-bag intravenous solutions (hereafter referred to as "soft bags"). This includes detecting leaks at defects such as micro-pores in the soft bag (larger than 0.1 μm), compression seals along the bag body, welds at the bag opening, and welds at the bag tubing connection points.

How it works

The soft bags to be inspected are evenly spaced into two rows as they move along the conveyor belt (1), then conveyed into the inspection channel (2). The inspection channel uses roller conveyance and is divided into two separate inspection areas—front and back—each equipped with four inspection stations. At each station, the position for detection can be adjusted as needed, ensuring that every part of the soft bag is thoroughly checked for leaks. Non-conforming products are automatically rejected by the waste-disposal mechanism (3), while合格品 are discharged from the conveyor belt (4).

Detection Principle

V is a high-frequency, high-voltage detection power supply, with its two ends connected respectively to the emitter and receiver electrodes. C1 and C2 represent the capacitance values between the electrodes and the capacitors (since the insulating soft-bag membrane prevents direct contact between the electrodes and the medicinal solution, capacitance is thus generated). R denotes the resistance of the medicinal solution. When the soft bag remains intact without leakage, a minute induced current I1 is produced. However, if the soft bag develops a leak, the capacitance between the bag membrane and the electrodes disappears, causing the capacitive reactance to drop to zero. As a result, the circuit generates a significantly larger microcurrent I2. By simply comparing the magnitudes of these microcurrents, it becomes possible to determine whether the soft bag has leaked or not.

Main Technical Parameters

1. Production Capacity: 2,500–3,000 bags/hour

2. Capacitance: 2.6 kW, 380V 50Hz

3. Power output range: 10kV–45kV

4. Frequency output range: 500Hz to 50kHz

5. Power Channel Count: Outputs multiple high-frequency, high-voltage power channels

6. Compressed air: 0.1–1.0 MPa

7. Weight: Approximately 1200 kg

8. Overall dimensions: 4489 × 1200 × 1500 mm (L × W × H)

Main advantages

1. There is no risk of secondary contamination from the drug. By eliminating the use of liquid substances like dye solutions, we prevent issues such as contamination of the medication.

2. Capable of detecting ultra-fine pores and cracks (above 0.1 micrometer), offering leak detection accuracy that traditional methods lack.

3. Fully automatic, full-scale online leak testing performed bag by bag. It can operate either as a standalone unit or be integrated into a connected production line, enabling a complete set of automated assembly-line operations.

4. Due to the low energy and short duration of the applied load, there are no side effects on the liquid medicine inside the product; this enables non-destructive inspection of soft bags.

5. A single device can be used for leak testing of soft bags with various fill volume specifications.

6. Special requirements. The critical areas of soft bags can be inspected according to the needs of different users.

7. The entire machine features a compact structure and an aesthetically pleasing design. Its user-friendly touchscreen interface offers powerful functions such as control, display, and data acquisition and storage.

8. Voltage and frequency can be adjusted according to different products.

9. Provide validation documents and a validation plan

Next Page

Next Page

Related Products

Inquiry