Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

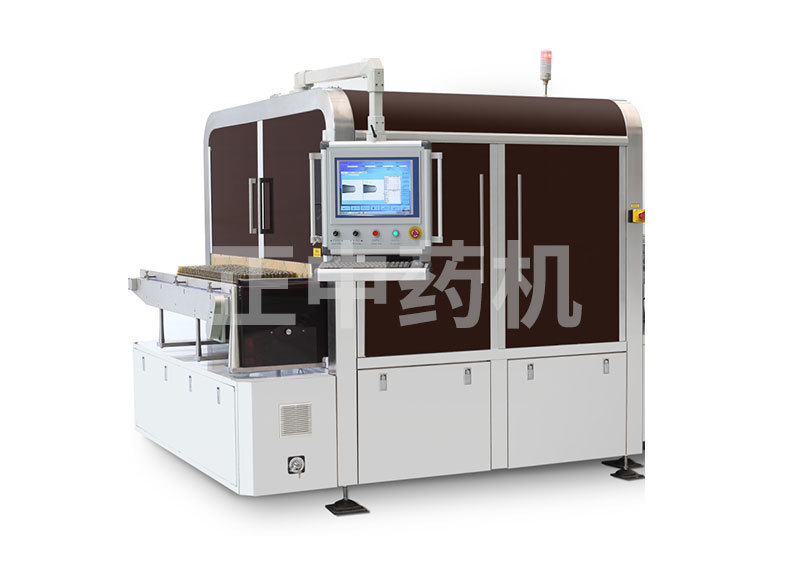

JKZ400/30 Vial Freeze-Drying Agent Automatic Inspection Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Automatic inspection machine for lyophilized preparations in vials

Details

Main Uses

This machine is designed for the detection of visible foreign objects and visual defects in lyophilized injections packaged in molded or molded-and-sealed vials at pharmaceutical factories.

How it works

The device is divided into the following main components: bottle-infeed conveyor mechanism, rotary table inspection mechanism, camera light source tracking mechanism, bottle-outfeed wheel separation mechanism, servo motor control mechanism, as well as the machine body and protective enclosure system.

Once the pharmaceutical products enter the conveyor belt, they are transported horizontally to the bottle-in-feed indexing wheel. This wheel evenly spaces the products apart before continuously feeding them into the corresponding rotary bottle holders located in the inspection zone. A pressing head aligned with each holder securely holds the product in place, ensuring that the pressing head, the product being inspected, and the rotary holder form an independent detection unit. As the rotary table rotates at a constant speed, the inspected products complete one full rotation as they move through the inspection area. At this point, a high-speed camera captures images of the products for verification. The inspection focuses on specific areas: the side of the compact powder, the top surface of the compact, the bottle’s exterior appearance, the cap-sealing mechanism, the bottle base, and the decorative cap. If any defect is detected during the inspection process, the product is immediately flagged for rejection. Finally, when the inspected products reach the bottle-out indexing wheel, the corresponding pressing heads release the items via a cam mechanism. The finished products then proceed to the bottle-out wheel, where a reject device separates the合格品 (qualified products) from the不合格品 (non-qualified products).

Testing Items

Including inspections for product defects, container appearance flaws, and sealing imperfections, the main inspection items are as follows:

- Bottle cap section: Ensure the aluminum-cap composite cap is intact, and check whether the crimping is even and aesthetically pleasing (looking for defects such as crooked crimps, burrs, wrinkles, or other imperfections).

- Check the bottleneck for any rubber stoppers;

- Is the transparent upper part of the bottle caused by freeze-drying spots formed from liquid droplets splashing?

- The lower part of the bottle—specifically, whether the freeze-drying of the drug-containing section is uniform, whether there are any areas where freeze-drying is incomplete, and whether visible foreign particles are present on the freeze-dried surface—needs to be carefully inspected.

- Is the freeze-drying uniform and complete at the bottom of the bottle, and are there any visible foreign particles on the freeze-dried surface?

- Are there any visible foreign particles in the freeze-dried drug portion inside the vial?

- Are there any cracks visible on the bottle body and bottom, etc.?

- Overfilling, underfilling, or empty bottles;

Main Technical Parameters

Applicable Scope: Molded or Controlled Lyophilized Injectable Vials, 2–25 mL

Detection speed: 400 × (1 ± 5%) tubes/minute

Motors and Power: Servo Motors: 0.4–2 kW; 11 units

Capacitance: 8 kW, 380 (1 ± 5%) V, three-phase AC, 50 Hz

The workbench height is: 900mm

External dimensions: 3380 × 1830 × 2020 mm (length × width × height)

Net weight: Approximately 2,600 kg

Key Features

- Detection accuracy is adjustable, catering to the varying inspection requirements of different projects.

- The conveyor system, designed with patented technology, ensures smooth and seamless transport of the objects being inspected, delivering excellent detection performance.

- Multiple components now use servo motor control instead of traditional mechanical transmission, and the control and detection programs have been fully integrated, significantly enhancing the precision requirements for inspected items.

- The standard components feature a quick-release locating pin design, making component replacement simple and adjustments convenient.

- Employing high-resolution, imported industrial cameras allows for magnifying defect details, delivering detection accuracy and results that surpass those of manual inspection.

- Up to six workstation inspection stations can detect defects in all parts.

- Key components of the equipment are all manufactured using precision CNC machines, ensuring the accuracy and quality of the parts.

- The entire machine boasts a sleek and elegant design, with components such as the machine body plate and baseplate featuring a special protective plastic coating.

- Key components such as the complete machine's transmission bearings, electrical elements, and machine vision systems are all sourced from first-tier domestic or internationally renowned brands, both imported and domestically produced.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

This machine is designed for the detection of visible foreign objects and visual defects in lyophilized injections packaged in molded or molded-and-sealed vials at pharmaceutical factories.

How it works

The device is divided into the following main components: bottle-infeed conveyor mechanism, rotary table inspection mechanism, camera light source tracking mechanism, bottle-outfeed wheel separation mechanism, servo motor control mechanism, as well as the machine body and protective enclosure system.

Once the pharmaceutical products enter the conveyor belt, they are transported horizontally to the bottle-in-feed indexing wheel. This wheel evenly spaces the products apart before continuously feeding them into the corresponding rotary bottle holders located in the inspection zone. A pressing head aligned with each holder securely holds the product in place, ensuring that the pressing head, the product being inspected, and the rotary holder form an independent detection unit. As the rotary table rotates at a constant speed, the inspected products complete one full rotation as they move through the inspection area. At this point, a high-speed camera captures images of the products for verification. The inspection focuses on specific areas: the side of the compact powder, the top surface of the compact, the bottle’s exterior appearance, the cap-sealing mechanism, the bottle base, and the decorative cap. If any defect is detected during the inspection process, the product is immediately flagged for rejection. Finally, when the inspected products reach the bottle-out indexing wheel, the corresponding pressing heads release the items via a cam mechanism. The finished products then proceed to the bottle-out wheel, where a reject device separates the合格品 (qualified products) from the不合格品 (non-qualified products).

Testing Items

Including inspections for product defects, container appearance flaws, and sealing imperfections, the main inspection items are as follows:

- Bottle cap section: Ensure the aluminum-cap composite cap is intact, and check whether the crimping is even and aesthetically pleasing (looking for defects such as crooked crimps, burrs, wrinkles, or other imperfections).

- Check the bottleneck for any rubber stoppers;

- Is the transparent upper part of the bottle caused by freeze-drying spots formed from liquid droplets splashing?

- The lower part of the bottle—specifically, whether the freeze-drying of the drug-containing section is uniform, whether there are any areas where freeze-drying is incomplete, and whether visible foreign particles are present on the freeze-dried surface—needs to be carefully inspected.

- Is the freeze-drying uniform and complete at the bottom of the bottle, and are there any visible foreign particles on the freeze-dried surface?

- Are there any visible foreign particles in the freeze-dried drug portion inside the vial?

- Are there any cracks visible on the bottle body and bottom, etc.?

- Overfilling, underfilling, or empty bottles;

Main Technical Parameters

Applicable Scope: Molded or Controlled Lyophilized Injectable Vials, 2–25 mL

Detection speed: 400 × (1 ± 5%) tubes/minute

Motors and Power: Servo Motors: 0.4–2 kW; 11 units

Capacitance: 8 kW, 380 (1 ± 5%) V, three-phase AC, 50 Hz

The workbench height is: 900mm

External dimensions: 3380 × 1830 × 2020 mm (length × width × height)

Net weight: Approximately 2,600 kg

Key Features

- Detection accuracy is adjustable, catering to the varying inspection requirements of different projects.

- The conveyor system, designed with patented technology, ensures smooth and seamless transport of the objects being inspected, delivering excellent detection performance.

- Multiple components now use servo motor control instead of traditional mechanical transmission, and the control and detection programs have been fully integrated, significantly enhancing the precision requirements for inspected items.

- The standard components feature a quick-release locating pin design, making component replacement simple and adjustments convenient.

- Employing high-resolution, imported industrial cameras allows for magnifying defect details, delivering detection accuracy and results that surpass those of manual inspection.

- Up to six workstation inspection stations can detect defects in all parts.

- Key components of the equipment are all manufactured using precision CNC machines, ensuring the accuracy and quality of the parts.

- The entire machine boasts a sleek and elegant design, with components such as the machine body plate and baseplate featuring a special protective plastic coating.

- Key components such as the complete machine's transmission bearings, electrical elements, and machine vision systems are all sourced from first-tier domestic or internationally renowned brands, both imported and domestically produced.

Related Products

Inquiry