Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

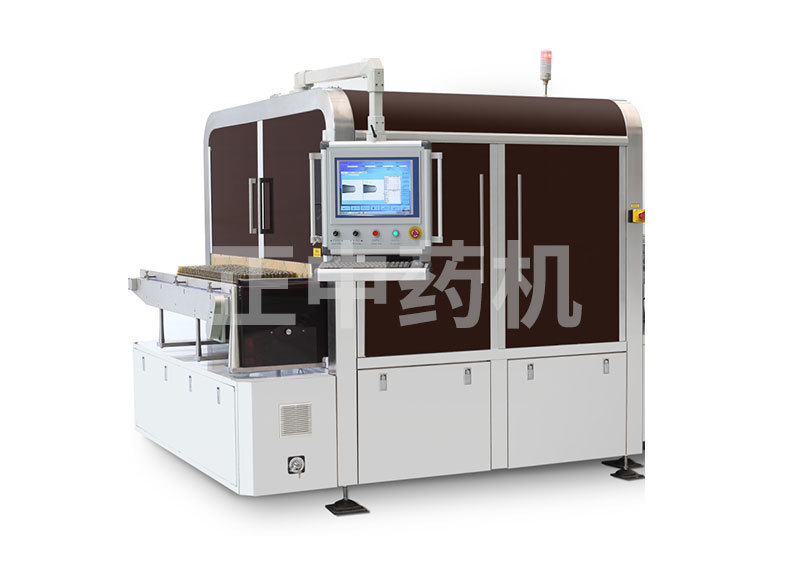

LYWD480 Vial Freeze-Drying Agent & Residual Oxygen Detection Integrated Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Automatic inspection machine for lyophilized preparations in vials

Details

Main Uses

Primarily used for detecting surface contaminants, visual defects, and fill volume in lyophilized powder vials, as well as testing gas tightness.

How it works

The testing of pharmaceuticals is divided into two parts: lyophilized product visual inspection and residual oxygen content testing. The detection principles are as follows:

Lyophilized Agent Light Inspection: Utilizing machine vision principles, the bottles to be inspected enter the main conveyor belt via a bottle-feeding wheel and rotate steadily for more than one full cycle. Simultaneously, a high-speed camera captures multiple images from different angles, transmitting these images to a distributed industrial computer. The computer’s inspection program then analyzes and evaluates the images to determine whether the inspected pharmaceutical products meet quality standards, automatically separating合格品 (qualified products) from 不合格产品 (non-qualified products) and directing them out of the production line.

Residual Oxygen Detection: It employs the principle of laser spectroscopy. The main conveyor is equipped with a semiconductor laser detection system, whose wavelength is precisely tuned to match the absorption wavelength of oxygen. As the laser beam passes through the bottle being inspected, a laser absorber positioned at the opposite end of the bottle captures the oxygen absorption signal for analysis, enabling automatic determination of whether the bottle meets quality standards—and promptly separating any nonconforming products.

Work Process

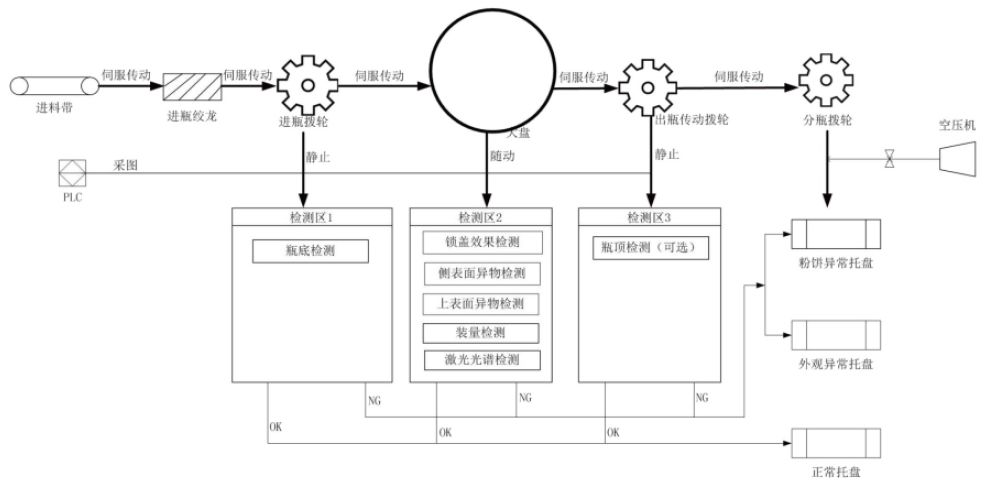

The conveyor belt delivers the samples to be inspected, which are then divided into individual bottles by the screw feeder before entering the equipment’s infeed bottle indexing wheel, inspection turntable, and outfeed bottle transmission indexing wheel—key detection stations for real-time online inspection. Based on the immediate inspection results, the bottle-dividing indexing wheel directs each sample to the corresponding loading tray.

The equipment is equipped with a total of 7 inspection stations located on the bottle-feeding wheel, the detection大盘, and the bottle-discharging transmission wheel. The overall process flow and station distribution of the equipment are shown in Figure 1.

Main Technical Parameters

Applicable range: Lyophilized powder for injection in 2–30 mL vials

Detection speed: 480 tubes/min (maximum)

Capacitance: 8 kW, 380 (1 ± 5%) V, three-phase AC, 50 Hz

The workbench height is: 900mm

External dimensions: 3020 × 1910 × 2020 (length × width × height)

Net weight: 2600 kg

Main Testing Items

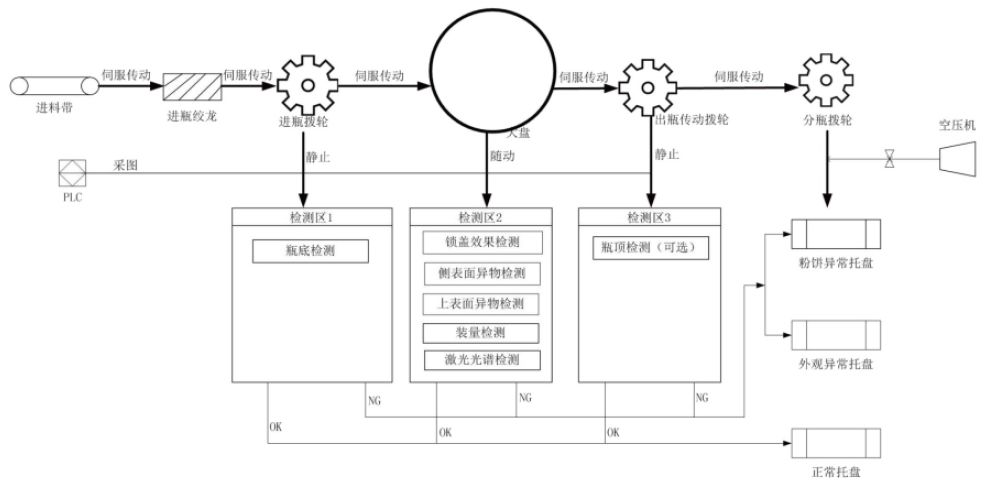

The process includes three parts: surface foreign object detection, appearance defect inspection, and gas leak-tightness testing; each part corresponds to one or more inspection stations. The specific inspection items for each station, along with their distribution areas on the bottle body, are illustrated in Figure 2.

The equipment is equipped with an optical-path high-frequency switching system. The upper-surface foreign-object detection station, the side-surface foreign-object detection station, and the fill-level inspection station all feature two distinct lighting solutions. Each station uses a high-speed camera to alternately capture images of the bottle bodies under two different illumination conditions, which helps improve the detection rate of defects such as foreign objects and cracks.

Key Features

- This equipment is independently developed and innovatively integrates freeze-drying agent lamp inspection technology with residual oxygen detection technology, providing a single, comprehensive system solution for visual defect and leak-tightness testing of lyophilized powder products in vials. At the same time, the equipment also boasts the following advantages:

- Integrating computer vision inspection with laser spectroscopic analysis, it features a fully servo-driven, multi-station design.

- High detection accuracy and adjustable settings: This machine is equipped with a high-resolution industrial camera, delivering detection precision that surpasses manual visual inspection. Moreover, the detection accuracy is quantified, allowing users to freely adjust it according to their specific needs.

- The inspection is conducted using high-speed industrial cameras. The visual inspection system is equipped with 6 dedicated inspection stations, capturing 10 sets of independent inspection images. At each tracking station, a single camera captures no fewer than 16 images, while a total of 98 inspection images are collected for each individual bottle.

- Fully servo-controlled: The entire machine is driven by full-servo motors, featuring a compact structure and stable transmission, which effectively minimizes bottle breakage during mechanical operation.

- Flexible Inspection: All component parts of the equipment feature a pin-and-hole design, and the large plate is equipped with a lifting mechanism, making it easy and quick to switch between different specifications.

- Audit Trail: The software features 3-4 levels of user permissions, with customizable operation rights for different users; all user activities, parameter modifications, and production data are fully traceable.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

Primarily used for detecting surface contaminants, visual defects, and fill volume in lyophilized powder vials, as well as testing gas tightness.

How it works

The testing of pharmaceuticals is divided into two parts: lyophilized product visual inspection and residual oxygen content testing. The detection principles are as follows:

Lyophilized Agent Light Inspection: Utilizing machine vision principles, the bottles to be inspected enter the main conveyor belt via a bottle-feeding wheel and rotate steadily for more than one full cycle. Simultaneously, a high-speed camera captures multiple images from different angles, transmitting these images to a distributed industrial computer. The computer’s inspection program then analyzes and evaluates the images to determine whether the inspected pharmaceutical products meet quality standards, automatically separating合格品 (qualified products) from 不合格产品 (non-qualified products) and directing them out of the production line.

Residual Oxygen Detection: It employs the principle of laser spectroscopy. The main conveyor is equipped with a semiconductor laser detection system, whose wavelength is precisely tuned to match the absorption wavelength of oxygen. As the laser beam passes through the bottle being inspected, a laser absorber positioned at the opposite end of the bottle captures the oxygen absorption signal for analysis, enabling automatic determination of whether the bottle meets quality standards—and promptly separating any nonconforming products.

Work Process

The conveyor belt delivers the samples to be inspected, which are then divided into individual bottles by the screw feeder before entering the equipment’s infeed bottle indexing wheel, inspection turntable, and outfeed bottle transmission indexing wheel—key detection stations for real-time online inspection. Based on the immediate inspection results, the bottle-dividing indexing wheel directs each sample to the corresponding loading tray.

The equipment is equipped with a total of 7 inspection stations located on the bottle-feeding wheel, the detection大盘, and the bottle-discharging transmission wheel. The overall process flow and station distribution of the equipment are shown in Figure 1.

Main Technical Parameters

Applicable range: Lyophilized powder for injection in 2–30 mL vials

Detection speed: 480 tubes/min (maximum)

Capacitance: 8 kW, 380 (1 ± 5%) V, three-phase AC, 50 Hz

The workbench height is: 900mm

External dimensions: 3020 × 1910 × 2020 (length × width × height)

Net weight: 2600 kg

Main Testing Items

The process includes three parts: surface foreign object detection, appearance defect inspection, and gas leak-tightness testing; each part corresponds to one or more inspection stations. The specific inspection items for each station, along with their distribution areas on the bottle body, are illustrated in Figure 2.

The equipment is equipped with an optical-path high-frequency switching system. The upper-surface foreign-object detection station, the side-surface foreign-object detection station, and the fill-level inspection station all feature two distinct lighting solutions. Each station uses a high-speed camera to alternately capture images of the bottle bodies under two different illumination conditions, which helps improve the detection rate of defects such as foreign objects and cracks.

Key Features

- This equipment is independently developed and innovatively integrates freeze-drying agent lamp inspection technology with residual oxygen detection technology, providing a single, comprehensive system solution for visual defect and leak-tightness testing of lyophilized powder products in vials. At the same time, the equipment also boasts the following advantages:

- Integrating computer vision inspection with laser spectroscopic analysis, it features a fully servo-driven, multi-station design.

- High detection accuracy and adjustable settings: This machine is equipped with a high-resolution industrial camera, delivering detection precision that surpasses manual visual inspection. Moreover, the detection accuracy is quantified, allowing users to freely adjust it according to their specific needs.

- The inspection is conducted using high-speed industrial cameras. The visual inspection system is equipped with 6 dedicated inspection stations, capturing 10 sets of independent inspection images. At each tracking station, a single camera captures no fewer than 16 images, while a total of 98 inspection images are collected for each individual bottle.

- Fully servo-controlled: The entire machine is driven by full-servo motors, featuring a compact structure and stable transmission, which effectively minimizes bottle breakage during mechanical operation.

- Flexible Inspection: All component parts of the equipment feature a pin-and-hole design, and the large plate is equipped with a lifting mechanism, making it easy and quick to switch between different specifications.

- Audit Trail: The software features 3-4 levels of user permissions, with customizable operation rights for different users; all user activities, parameter modifications, and production data are fully traceable.

Previous Page

Previous Page

Related Products

Inquiry