Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

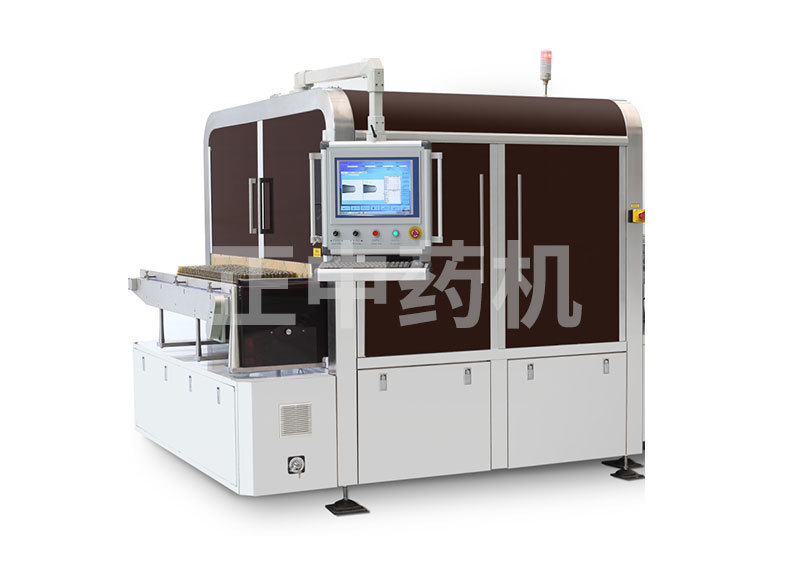

JYWZ400 Pre-Filled Syringe Automatic Foreign Object Inspection Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Automatic foreign object inspection machine for glass bottle intravenous infusions

Details

Main Uses

The equipment is primarily used for detecting visible foreign objects and certain appearance defects in water-based injectable drugs, such as pre-filled syringes, in pharmaceutical manufacturing plants. Foreign object detection items include glass shards, hair, and agglomerates, while appearance inspection items cover defects like those found on rubber stoppers and cone caps.

How it works

Utilize machine vision principles to detect visible foreign objects and inspect appearance.

Visible Foreign Object Detection: The product being inspected is rapidly braked while spinning at high speed, while the liquid inside the container continues to rotate rapidly due to inertia. At this moment, the machine vision system captures multiple images continuously, analyzes them, and determines whether the product meets quality standards.

Appearance defect detection: The product to be inspected is slowly rotated more than 360 degrees, and simultaneously, the machine vision system continuously captures and analyzes images to determine whether the product’s appearance meets the quality standards.

Process Flow

Incoming products → Screw conveyor feeds bottles into the machine—edge crimping and bottom-side stopper inspection → Bottle turns 180° → Bottle transfer to a disc for cone cap detection → Side-of-stopper inspection → Foreign object detection → Visual inspection with lighting, then bottle is transferred to another disc → Bottles exit via screw conveyor → Bottle turns 180° again—qualified and non-qualified products are discharged separately

Main Technical Parameters

Production capacity: 400 × (1 ±10%) bottles per minute.

Applicable specifications: 1–20 mL

Voltage: 380V; 50Hz

Total power: 9.5 kW

Working height: 960mm

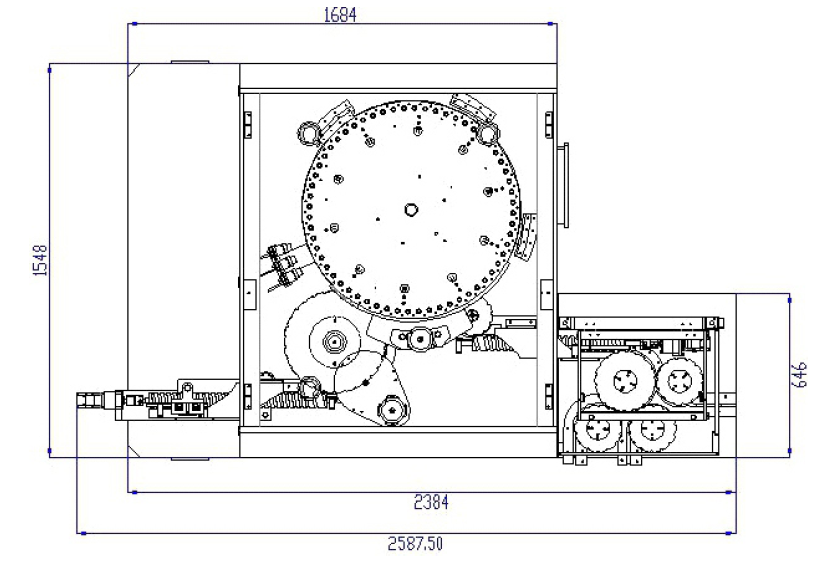

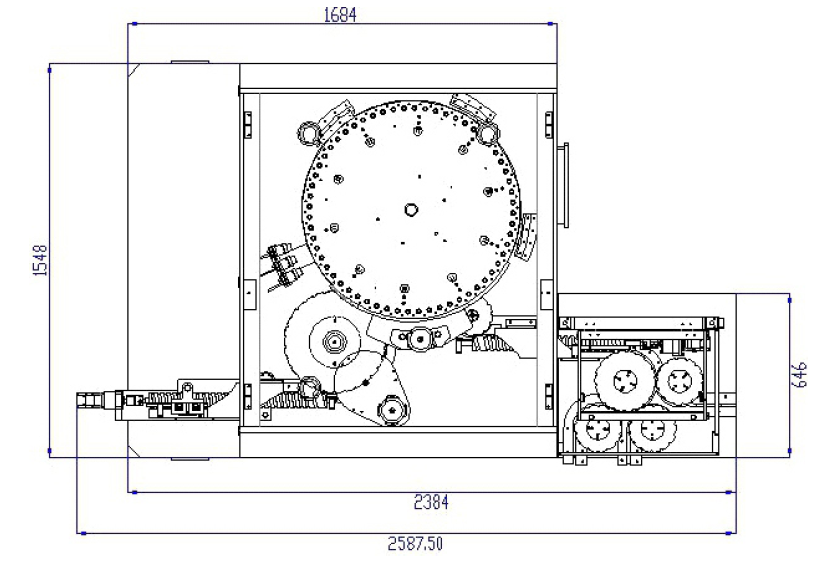

External dimensions: 2587.5 x 1544 x 2000 (mm) (L × W × H)

Net weight: Approximately 2000 kg

Workbench height: 925mm

Key Features

- The entire machine features servo-driven operation, with a compact structure, smooth running, and reliable safety.

- Specifications can be changed easily and quickly.

- Utilizing ultra-high-speed, high-resolution industrial cameras for precise detection.

- 360-degree, all-around detection with no blind spots.

- All critical electrical components, bearings, and more are entirely自主研发, utilizing first-tier domestic and international brands, with patented designs incorporated in multiple areas, ensuring complete independent intellectual property rights.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

The equipment is primarily used for detecting visible foreign objects and certain appearance defects in water-based injectable drugs, such as pre-filled syringes, in pharmaceutical manufacturing plants. Foreign object detection items include glass shards, hair, and agglomerates, while appearance inspection items cover defects like those found on rubber stoppers and cone caps.

How it works

Utilize machine vision principles to detect visible foreign objects and inspect appearance.

Visible Foreign Object Detection: The product being inspected is rapidly braked while spinning at high speed, while the liquid inside the container continues to rotate rapidly due to inertia. At this moment, the machine vision system captures multiple images continuously, analyzes them, and determines whether the product meets quality standards.

Appearance defect detection: The product to be inspected is slowly rotated more than 360 degrees, and simultaneously, the machine vision system continuously captures and analyzes images to determine whether the product’s appearance meets the quality standards.

Process Flow

Incoming products → Screw conveyor feeds bottles into the machine—edge crimping and bottom-side stopper inspection → Bottle turns 180° → Bottle transfer to a disc for cone cap detection → Side-of-stopper inspection → Foreign object detection → Visual inspection with lighting, then bottle is transferred to another disc → Bottles exit via screw conveyor → Bottle turns 180° again—qualified and non-qualified products are discharged separately

Main Technical Parameters

Production capacity: 400 × (1 ±10%) bottles per minute.

Applicable specifications: 1–20 mL

Voltage: 380V; 50Hz

Total power: 9.5 kW

Working height: 960mm

External dimensions: 2587.5 x 1544 x 2000 (mm) (L × W × H)

Net weight: Approximately 2000 kg

Workbench height: 925mm

Key Features

- The entire machine features servo-driven operation, with a compact structure, smooth running, and reliable safety.

- Specifications can be changed easily and quickly.

- Utilizing ultra-high-speed, high-resolution industrial cameras for precise detection.

- 360-degree, all-around detection with no blind spots.

- All critical electrical components, bearings, and more are entirely自主研发, utilizing first-tier domestic and international brands, with patented designs incorporated in multiple areas, ensuring complete independent intellectual property rights.

Related Products

Inquiry