Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

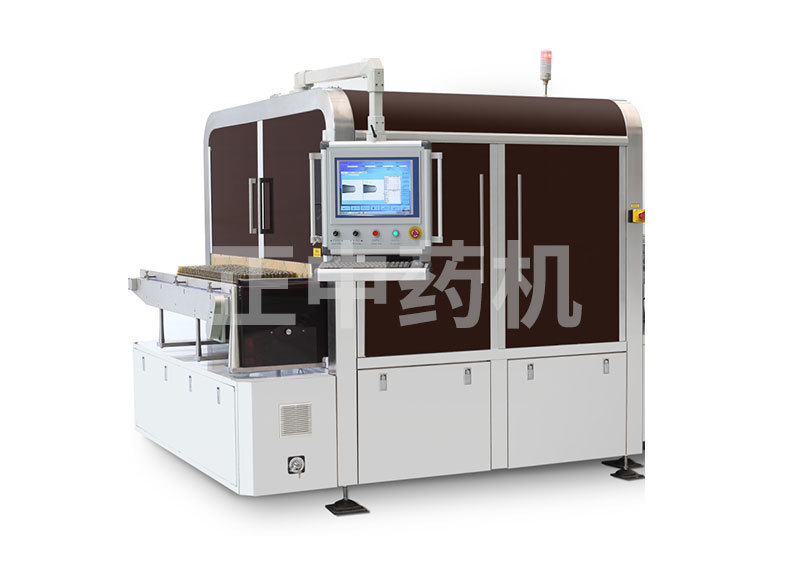

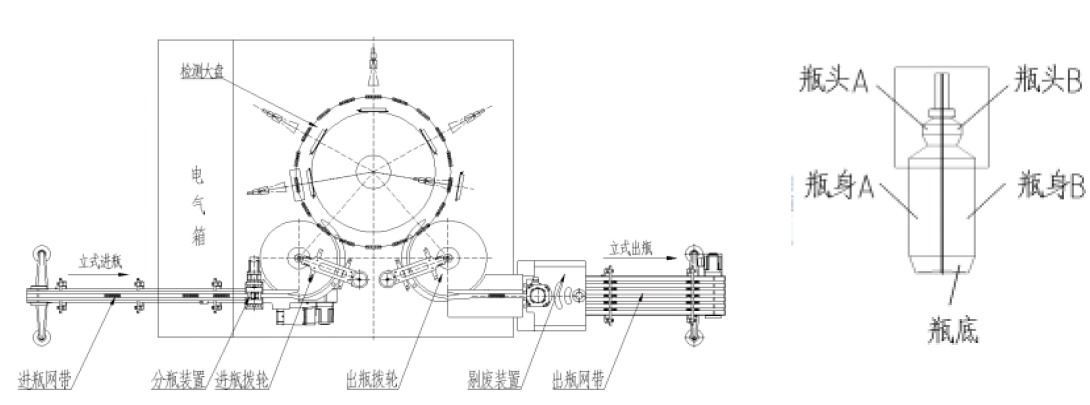

JYWALP80 Townhouse Plastic Ampoule Automatic Inspection Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

In-line plastic ampoule electronic micro-hole leak detector

Details

Main Uses

Primarily used for visual inspection of multi-dose plastic ampoules and eye-drop products (e.g., checking for liquid levels, black spots, missing parts, deformations, burrs, material buildup, etc.), as well as foreign object detection (such as detecting non-dispersible visible microparticles like cilia, black fragments, or white clumps).

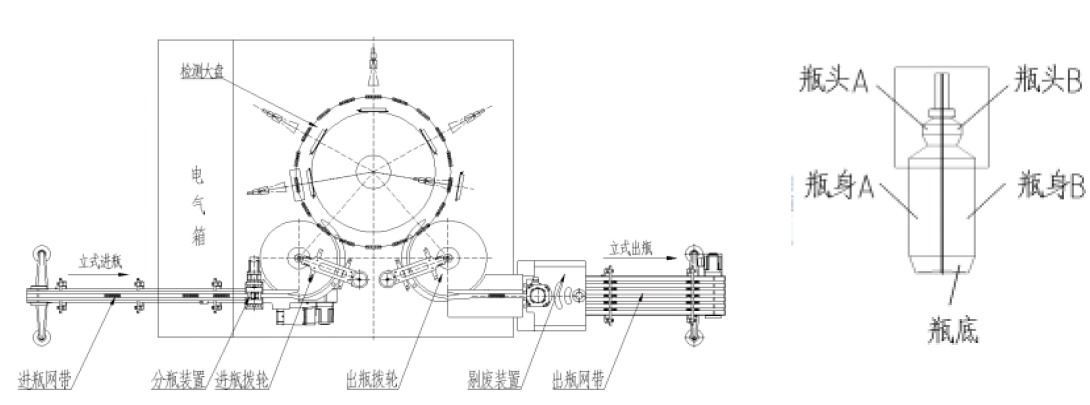

Work Flow

Once the products—whether filled, trimmed, or sterilized and dried—are completed (in an upright position with the bottle base in contact with the mesh conveyor belt)—they are transferred via the upstream mesh conveyor belt to the bottle-infeed conveyor belt of the lamp inspection equipment. The bottle-dividing mechanism then separates the continuously aligned, clustered products, allowing individual drug plates to enter the fixed slots of the infeed indexing wheel. At the designated station on the indexing wheel, a visual inspection station (Station 01) is positioned. As the drug plates move toward the tangent point where they meet the main rotating plate, a robotic arm mounted on the plate precisely grips and holds them, mimicking the manual lamp-inspection process to rotate the plates by ±180° or other angles up to ±N° as needed. Along the main plate’s set stations, visual inspection stations 02 through 07 are sequentially arranged. Among these, Stations 04, 05, and 06 are specifically equipped for foreign-object tracking and detection. When the drug plates reach the tangent point where they intersect with the outgoing indexing wheel, the robotic arm releases its grip, allowing the plates to settle into the fixed slots of the outgoing indexing wheel. A dedicated visual inspection station (Station 08) is positioned at this wheel’s designated location for final quality checks. Finally, the inspected drug plates are conveyed onto the outgoing mesh conveyor belt, where a rejection mechanism directs them into separate channels based on their status: one for cosmetic defects, another for foreign objects, a third reserved for potential future defects, and a fourth for合格品 (qualified products). From there, the good-quality plates proceed smoothly through the合格品 channel, ready for the next stage of production.

How it works

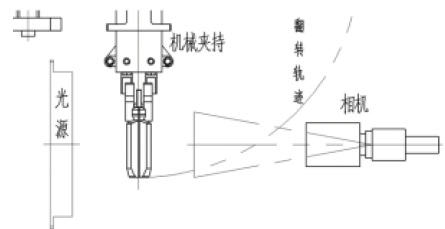

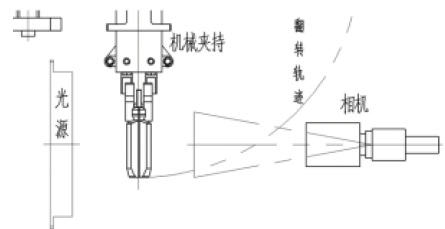

The inspection of the row-type plastic ampoule products is divided into two main parts: visual inspection and foreign object detection.

Appearance Inspection: Expose the product's external contour to the camera's field of view, dividing it into 5 inspection areas. Sequentially capture image data of qualified products' appearance features, and then use image comparison to determine whether the product has any visual defects.

Foreign object detection: Simulating the manual lamp inspection process, the drug plate is clamped and positioned. For different types of foreign objects, specific flipping angles of ±N° (where N ≤ 180°) are set at various inspection stations. A high-speed camera captures multiple images, enabling the development of an algorithm that outlines the motion trajectory of foreign objects within the drug container, ultimately allowing for accurate identification of the foreign object samples.

Main Technical Parameters

Application range: 1–20 ml multi-dose plastic ampoules and multi-dose plastic eye drops;

Detection accuracy: ≥40 μm;

Detection speed: ≤80 boards per minute (based on the standard of 5 vials per board);

Detection items: Visual defects such as level, missing parts, burrs, black spots, cilia, black marks, white marks, and foreign objects;

Capacitance: 10 kW, AV 380V, 50 Hz

Testing station: 8

Equipment working height: 940 ± 30 mm

Equipment dimensions: 4060mm x 1780mm x 2150mm (length x width x height)

Equipment net weight: 3,500 kg

Key Features

- Employing a completely innovative, independently developed detection structure and technology backed by full proprietary intellectual property rights;

- Suitable for a wide range of applications, meeting the visual and foreign object inspection requirements for 1–20 ml inline plastic products;

- Employing high-resolution industrial cameras and an advanced servo tracking system ensures the integrity and accuracy of the captured images, thereby guaranteeing highly precise and stable inspections.

- The large-scale robotic arm uses pneumatic gripping, while its flipping function is driven by an independent servo system, ensuring precise control and stable operation.

- The main machine features a servo-driven automatic lifting system, allowing for parameterized selection of different specifications and significantly reducing mold-change time.

- The main inspection area is completely separate from the transmission control area, making cleaning and maintenance even simpler.

- It features multiple fault alarms and protection functions; in case of abnormal operation or failure, the equipment will either sound an alarm or shut down, and display the cause of the malfunction.

- Stores detection data, operation records, alarm records, and process parameters for traceability, ensuring compliance with GMP requirements;

- Key components are manufactured using precision CNC machining; critical parts are sourced from leading international and domestic brands.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

Primarily used for visual inspection of multi-dose plastic ampoules and eye-drop products (e.g., checking for liquid levels, black spots, missing parts, deformations, burrs, material buildup, etc.), as well as foreign object detection (such as detecting non-dispersible visible microparticles like cilia, black fragments, or white clumps).

Work Flow

Once the products—whether filled, trimmed, or sterilized and dried—are completed (in an upright position with the bottle base in contact with the mesh conveyor belt)—they are transferred via the upstream mesh conveyor belt to the bottle-infeed conveyor belt of the lamp inspection equipment. The bottle-dividing mechanism then separates the continuously aligned, clustered products, allowing individual drug plates to enter the fixed slots of the infeed indexing wheel. At the designated station on the indexing wheel, a visual inspection station (Station 01) is positioned. As the drug plates move toward the tangent point where they meet the main rotating plate, a robotic arm mounted on the plate precisely grips and holds them, mimicking the manual lamp-inspection process to rotate the plates by ±180° or other angles up to ±N° as needed. Along the main plate’s set stations, visual inspection stations 02 through 07 are sequentially arranged. Among these, Stations 04, 05, and 06 are specifically equipped for foreign-object tracking and detection. When the drug plates reach the tangent point where they intersect with the outgoing indexing wheel, the robotic arm releases its grip, allowing the plates to settle into the fixed slots of the outgoing indexing wheel. A dedicated visual inspection station (Station 08) is positioned at this wheel’s designated location for final quality checks. Finally, the inspected drug plates are conveyed onto the outgoing mesh conveyor belt, where a rejection mechanism directs them into separate channels based on their status: one for cosmetic defects, another for foreign objects, a third reserved for potential future defects, and a fourth for合格品 (qualified products). From there, the good-quality plates proceed smoothly through the合格品 channel, ready for the next stage of production.

How it works

The inspection of the row-type plastic ampoule products is divided into two main parts: visual inspection and foreign object detection.

Appearance Inspection: Expose the product's external contour to the camera's field of view, dividing it into 5 inspection areas. Sequentially capture image data of qualified products' appearance features, and then use image comparison to determine whether the product has any visual defects.

Foreign object detection: Simulating the manual lamp inspection process, the drug plate is clamped and positioned. For different types of foreign objects, specific flipping angles of ±N° (where N ≤ 180°) are set at various inspection stations. A high-speed camera captures multiple images, enabling the development of an algorithm that outlines the motion trajectory of foreign objects within the drug container, ultimately allowing for accurate identification of the foreign object samples.

Main Technical Parameters

Application range: 1–20 ml multi-dose plastic ampoules and multi-dose plastic eye drops;

Detection accuracy: ≥40 μm;

Detection speed: ≤80 boards per minute (based on the standard of 5 vials per board);

Detection items: Visual defects such as level, missing parts, burrs, black spots, cilia, black marks, white marks, and foreign objects;

Capacitance: 10 kW, AV 380V, 50 Hz

Testing station: 8

Equipment working height: 940 ± 30 mm

Equipment dimensions: 4060mm x 1780mm x 2150mm (length x width x height)

Equipment net weight: 3,500 kg

Key Features

- Employing a completely innovative, independently developed detection structure and technology backed by full proprietary intellectual property rights;

- Suitable for a wide range of applications, meeting the visual and foreign object inspection requirements for 1–20 ml inline plastic products;

- Employing high-resolution industrial cameras and an advanced servo tracking system ensures the integrity and accuracy of the captured images, thereby guaranteeing highly precise and stable inspections.

- The large-scale robotic arm uses pneumatic gripping, while its flipping function is driven by an independent servo system, ensuring precise control and stable operation.

- The main machine features a servo-driven automatic lifting system, allowing for parameterized selection of different specifications and significantly reducing mold-change time.

- The main inspection area is completely separate from the transmission control area, making cleaning and maintenance even simpler.

- It features multiple fault alarms and protection functions; in case of abnormal operation or failure, the equipment will either sound an alarm or shut down, and display the cause of the malfunction.

- Stores detection data, operation records, alarm records, and process parameters for traceability, ensuring compliance with GMP requirements;

- Key components are manufactured using precision CNC machining; critical parts are sourced from leading international and domestic brands.

Next Page

Next Page

Related Products

Inquiry