Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

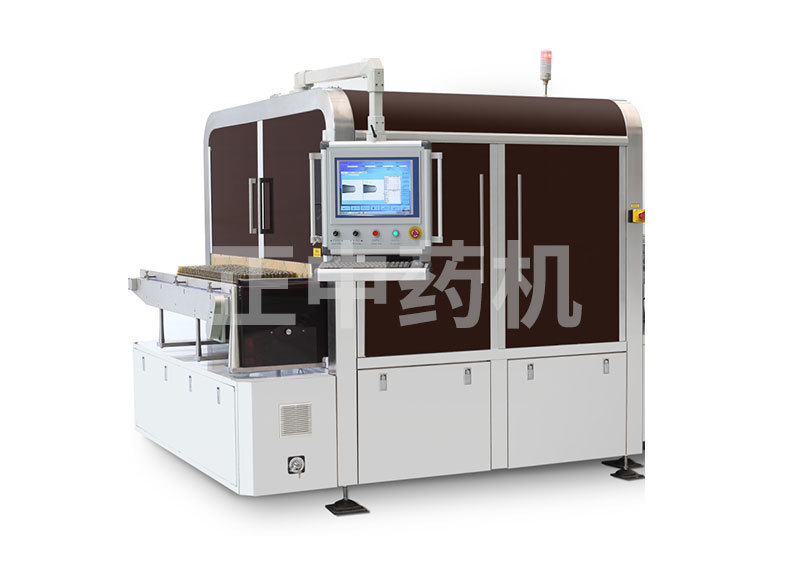

LPJL80 Townhouse Plastic Ampoule Electronic Micro-Pore Leak Detection Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

In-line plastic ampoule electronic micro-hole leak detector

Details

Main Uses

Comprehensive testing is conducted to detect leaks in co-packed plastic ampoules produced using the blow-fill-seal three-in-one process. It can also identify defects in other similar packaging products, such as co-packed eye drops and co-packed oral liquids.

How it works

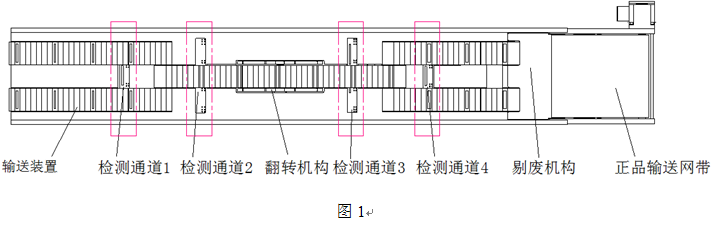

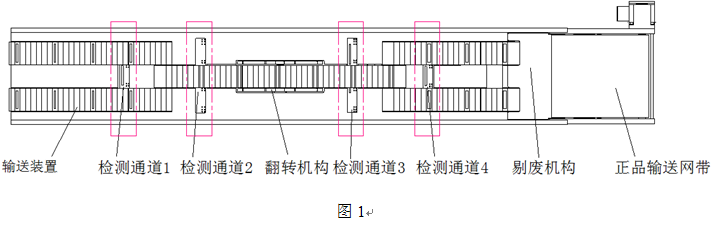

The row-type plastic ampoules are manually or automatically fed onto the infeed conveyor belt, which then accelerates to separate and deliver the products sequentially into the inspection stations. The conveying mechanism moves the row-type plastic ampoules toward the inspection channels, guiding them through Inspection Channel 1 and Channel 2 one after another. During this process, the bottle body, head, and tail of each ampoule are inspected individually. Next, the ampoules are flipped by a specialized wheel mechanism and sequentially conveyed through Inspection Channels 3 and 4, where the opposite sides—specifically the head, tail, and body—are checked for quality. Finally, a rejection mechanism separates the合格品 (qualified products) from the 不合格品 (unqualified products). The合格品 are then transferred via a dedicated conveyor belt to the next processing station, while the 不合格品 are directed by the same rejection mechanism into a waste collection bin (note that the bin is not shown in Figure 1—it must be provided by the user).

Detection Principle

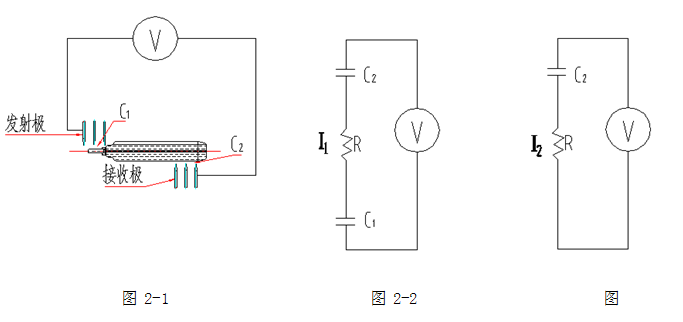

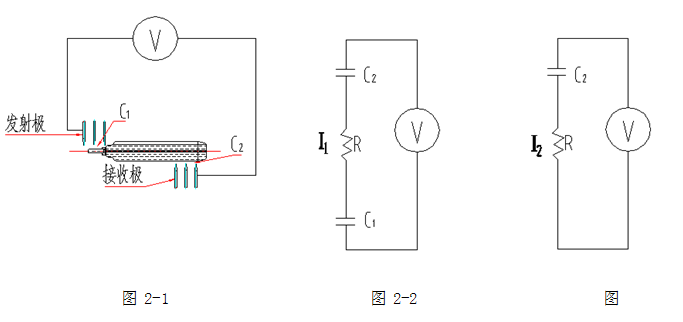

The detection principle is illustrated in Figure 2-1, where V represents a high-frequency, high-voltage power supply connected at its two ends to the emitter and receiver electrodes, respectively. C1 and C2 are the capacitances between the emitter electrode, the receiver electrode, and the solution—capacitances that arise because the container wall separates the solution from the electrodes, preventing direct contact. R denotes the electrical resistance of the solution.

When the row-type plastic ampoules are leak-free, the simplified circuit of the entire loop is shown in Figure 2-2, at which point the circuit generates a small current I1.

When a plastic ampoule in a row leaks, the electrode directly connects with the solution, causing the capacitance generated by the container wall to disappear. The simplified circuit of the entire loop is shown in Figure 2-3; at this point, a current I₂ will flow through the circuit.

By comparing the magnitudes of I1 and I2, it is possible to determine whether the row-type plastic ampoule has a leak.

Main Technical Parameters

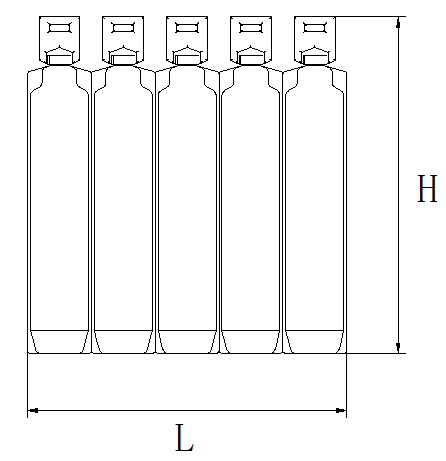

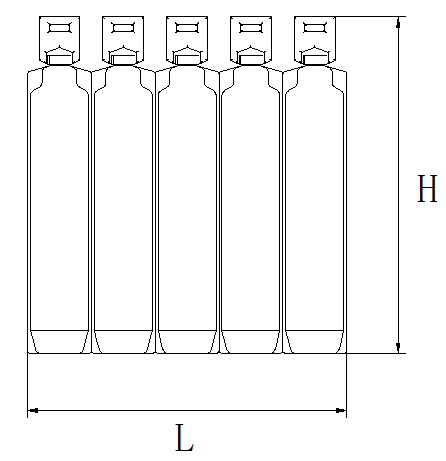

Applicable specifications: Terraced plastic ampoules with height ranging from 65 mm ≤ H ≤ 120 mm; length L ≤ 220 mm; (customization available based on customer samples)

Output: 0–80 rows/min

Capacitance: 3 kW, 380V 50Hz

Detection channel count: Multiple sets, customizable

High-frequency, high-voltage power supply voltage: Adjustable from 0 to 30 kV

External dimensions (L × W × H): 2800mm × 935mm × 1650mm

Weight: Approximately 1200 kg

Key Features

- Zero pollution. Since no liquid substances like dyes are used, there is no secondary contamination of the medication.

- High precision. It can detect micro-sized and larger holes, offering greater accuracy than traditional methods such as vacuum testing or staining.

- Full-scale inspection. Fully automated, full-process online inspection of pharmaceuticals row by row.

- Comprehensive multi-angle detection. Utilizing a patented technology-designed flip mechanism, the row-mounted plastic ampoules are turned over, enabling the emitter to inspect both the top and bottom surfaces of the ampoules—including the head, body, and tail—ensuring all-around, dead-zone-free detection.

- High safety: The energy applied to the row-type plastic ampoules is low, ensuring no side effects on the pharmaceutical products.

- Customized design. Arrange detection electrodes according to the customer's samples to achieve optimal detection performance.

- Control advanced systems with a user-friendly human-machine interface, equipped with robust data acquisition, storage, and control capabilities.

- Possessing fully independent intellectual property rights, it has already obtained multiple invention and utility model patents.

- Customizable fully automatic bottle-loading system available upon customer request (optional).

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

Comprehensive testing is conducted to detect leaks in co-packed plastic ampoules produced using the blow-fill-seal three-in-one process. It can also identify defects in other similar packaging products, such as co-packed eye drops and co-packed oral liquids.

How it works

The row-type plastic ampoules are manually or automatically fed onto the infeed conveyor belt, which then accelerates to separate and deliver the products sequentially into the inspection stations. The conveying mechanism moves the row-type plastic ampoules toward the inspection channels, guiding them through Inspection Channel 1 and Channel 2 one after another. During this process, the bottle body, head, and tail of each ampoule are inspected individually. Next, the ampoules are flipped by a specialized wheel mechanism and sequentially conveyed through Inspection Channels 3 and 4, where the opposite sides—specifically the head, tail, and body—are checked for quality. Finally, a rejection mechanism separates the合格品 (qualified products) from the 不合格品 (unqualified products). The合格品 are then transferred via a dedicated conveyor belt to the next processing station, while the 不合格品 are directed by the same rejection mechanism into a waste collection bin (note that the bin is not shown in Figure 1—it must be provided by the user).

Detection Principle

The detection principle is illustrated in Figure 2-1, where V represents a high-frequency, high-voltage power supply connected at its two ends to the emitter and receiver electrodes, respectively. C1 and C2 are the capacitances between the emitter electrode, the receiver electrode, and the solution—capacitances that arise because the container wall separates the solution from the electrodes, preventing direct contact. R denotes the electrical resistance of the solution.

When the row-type plastic ampoules are leak-free, the simplified circuit of the entire loop is shown in Figure 2-2, at which point the circuit generates a small current I1.

When a plastic ampoule in a row leaks, the electrode directly connects with the solution, causing the capacitance generated by the container wall to disappear. The simplified circuit of the entire loop is shown in Figure 2-3; at this point, a current I₂ will flow through the circuit.

By comparing the magnitudes of I1 and I2, it is possible to determine whether the row-type plastic ampoule has a leak.

Main Technical Parameters

Applicable specifications: Terraced plastic ampoules with height ranging from 65 mm ≤ H ≤ 120 mm; length L ≤ 220 mm; (customization available based on customer samples)

Output: 0–80 rows/min

Capacitance: 3 kW, 380V 50Hz

Detection channel count: Multiple sets, customizable

High-frequency, high-voltage power supply voltage: Adjustable from 0 to 30 kV

External dimensions (L × W × H): 2800mm × 935mm × 1650mm

Weight: Approximately 1200 kg

Key Features

- Zero pollution. Since no liquid substances like dyes are used, there is no secondary contamination of the medication.

- High precision. It can detect micro-sized and larger holes, offering greater accuracy than traditional methods such as vacuum testing or staining.

- Full-scale inspection. Fully automated, full-process online inspection of pharmaceuticals row by row.

- Comprehensive multi-angle detection. Utilizing a patented technology-designed flip mechanism, the row-mounted plastic ampoules are turned over, enabling the emitter to inspect both the top and bottom surfaces of the ampoules—including the head, body, and tail—ensuring all-around, dead-zone-free detection.

- High safety: The energy applied to the row-type plastic ampoules is low, ensuring no side effects on the pharmaceutical products.

- Customized design. Arrange detection electrodes according to the customer's samples to achieve optimal detection performance.

- Control advanced systems with a user-friendly human-machine interface, equipped with robust data acquisition, storage, and control capabilities.

- Possessing fully independent intellectual property rights, it has already obtained multiple invention and utility model patents.

- Customizable fully automatic bottle-loading system available upon customer request (optional).

Previous Page

Previous Page

Related Products

Inquiry