Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

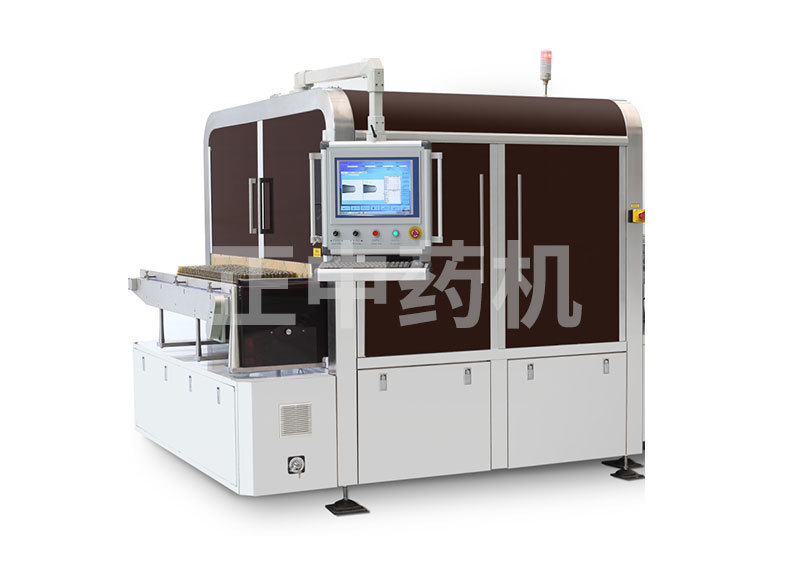

SJL200 Infusion Fully Automatic Electronic Micropore Leak Detection Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Fully automatic electronic microporous leak detector for infusion

Details

Main Uses

Primarily used for leak detection in infusion bottles (including both plastic and glass bottles).

How it works

The containers are conveyed along a track to the bottle-feeding indexing wheel, where they are evenly spaced. On the large turntable, 30 evenly distributed robotic arms pick up the bottles at a constant speed and then perform a 180° flip. After two such flips, the containers reach different stations for inspection of their upper and lower sections. Once inspection is complete, the bottles move to the bottle-discharging indexing wheel, where a reject mechanism separates the合格品 (qualified products) from the 不合格品 (defective products), directing each type into its own output track.

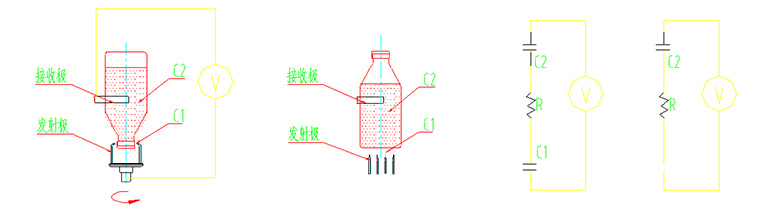

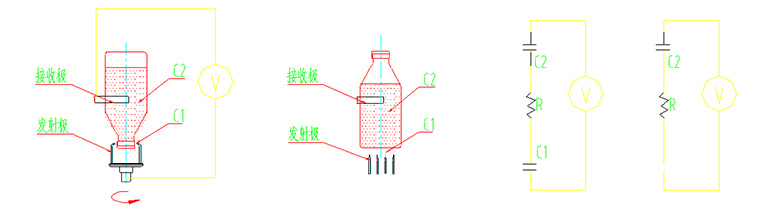

Detection Principle

V is a high-frequency, high-voltage detection power supply, with its two ends connected respectively to the emitter and receiver electrodes. C1 and C2 represent the capacitance values between the electrodes and the solution (since the electrode cannot come into direct contact with the solution due to the insulating bottle wall, capacitance is naturally formed). R denotes the resistance of the solution.

When the container remains leak-free, an induced microcurrent I1 is generated. However, if the container develops a leak, the capacitance between the bottle wall and the electrode disappears, causing the capacitive reactance to drop to zero. As a result, the circuit produces a significantly larger microcurrent I2. By comparing the magnitudes of these microcurrents, we can determine whether the container has a leak.

Main Technical Parameters

1. Scope of Application: 100–1000 ml Infusion Bottles (Plastic or Glass Bottles)

2. Production Capacity: 140–200 bottles/min

3. Capacitance: 4.6 kW, 380V 50Hz

4. Power output range: 10kV to 45kV

5. Frequency output range: 500Hz to 50kHz

6. Power supply channels: Outputs 4 channels of high-frequency, high-voltage power.

7. Weight: Approximately 2000 kg

8. Overall Dimensions: 1900 × 2120 × 1800 mm (L × W × H)

9. Bottle Conveying Track: 5450 × 570 × 960 mm (L × W × H)

Main advantages

1. No risk of secondary contamination. Since no liquid substances like dye solutions are used, there is no risk of contaminating the product or causing related issues.

2. Capable of detecting ultra-fine pores (above 0.1 micrometer), offering leak detection accuracy that other methods lack.

3. Fully automatic, with individual leak tests conducted on every single item. Production can be carried out either as standalone units or in a connected line.

4. Due to the low energy and short duration of the load applied to the product, there are no adverse effects on the liquid inside the product.

5. Perform non-destructive testing on the container, setting different loading voltages according to the container's varying dielectric strength values, thereby protecting the container's material itself.

6. Suitable for leak testing of various packaging containers, such as large infusion bottles (including glass and plastic bottles), as well as products like blow-fill-seal three-in-one systems.

7. Can detect key areas of the container (such as the neck and bottom) according to user requirements.

8. The entire machine uses synchronous belt drive, ensuring smooth operation with a low breakage rate.

9. Compact in structure, aesthetically pleasing in design, and featuring a quick-release mold assembly with locating-pin connections for convenient daily maintenance.

10. Human-machine-friendly touchscreen interface with powerful functions such as control, display, and data acquisition.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

Primarily used for leak detection in infusion bottles (including both plastic and glass bottles).

How it works

The containers are conveyed along a track to the bottle-feeding indexing wheel, where they are evenly spaced. On the large turntable, 30 evenly distributed robotic arms pick up the bottles at a constant speed and then perform a 180° flip. After two such flips, the containers reach different stations for inspection of their upper and lower sections. Once inspection is complete, the bottles move to the bottle-discharging indexing wheel, where a reject mechanism separates the合格品 (qualified products) from the 不合格品 (defective products), directing each type into its own output track.

Detection Principle

V is a high-frequency, high-voltage detection power supply, with its two ends connected respectively to the emitter and receiver electrodes. C1 and C2 represent the capacitance values between the electrodes and the solution (since the electrode cannot come into direct contact with the solution due to the insulating bottle wall, capacitance is naturally formed). R denotes the resistance of the solution.

When the container remains leak-free, an induced microcurrent I1 is generated. However, if the container develops a leak, the capacitance between the bottle wall and the electrode disappears, causing the capacitive reactance to drop to zero. As a result, the circuit produces a significantly larger microcurrent I2. By comparing the magnitudes of these microcurrents, we can determine whether the container has a leak.

Main Technical Parameters

1. Scope of Application: 100–1000 ml Infusion Bottles (Plastic or Glass Bottles)

2. Production Capacity: 140–200 bottles/min

3. Capacitance: 4.6 kW, 380V 50Hz

4. Power output range: 10kV to 45kV

5. Frequency output range: 500Hz to 50kHz

6. Power supply channels: Outputs 4 channels of high-frequency, high-voltage power.

7. Weight: Approximately 2000 kg

8. Overall Dimensions: 1900 × 2120 × 1800 mm (L × W × H)

9. Bottle Conveying Track: 5450 × 570 × 960 mm (L × W × H)

Main advantages

1. No risk of secondary contamination. Since no liquid substances like dye solutions are used, there is no risk of contaminating the product or causing related issues.

2. Capable of detecting ultra-fine pores (above 0.1 micrometer), offering leak detection accuracy that other methods lack.

3. Fully automatic, with individual leak tests conducted on every single item. Production can be carried out either as standalone units or in a connected line.

4. Due to the low energy and short duration of the load applied to the product, there are no adverse effects on the liquid inside the product.

5. Perform non-destructive testing on the container, setting different loading voltages according to the container's varying dielectric strength values, thereby protecting the container's material itself.

6. Suitable for leak testing of various packaging containers, such as large infusion bottles (including glass and plastic bottles), as well as products like blow-fill-seal three-in-one systems.

7. Can detect key areas of the container (such as the neck and bottom) according to user requirements.

8. The entire machine uses synchronous belt drive, ensuring smooth operation with a low breakage rate.

9. Compact in structure, aesthetically pleasing in design, and featuring a quick-release mold assembly with locating-pin connections for convenient daily maintenance.

10. Human-machine-friendly touchscreen interface with powerful functions such as control, display, and data acquisition.

Next Page

Next Page

Related Products

Inquiry