Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

JAYL600 fully automatic lamp inspection and leak detection integrated machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Fully automatic electronic microporous leak detector for infusion

Details

Main Use

Mainly used for the detection of visible foreign objects (including glass chips, fibers, hair, white patches, white spots, etc.), liquid level, and leakage (micro-holes, cracks) in ampoules; also applicable to oral liquids and penicillin bottle injections.

Detection Principle

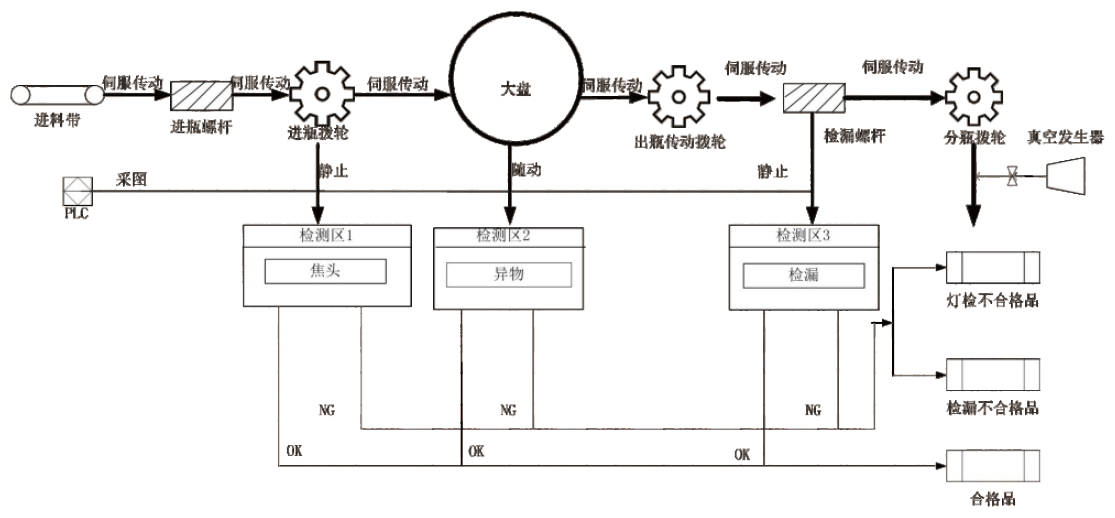

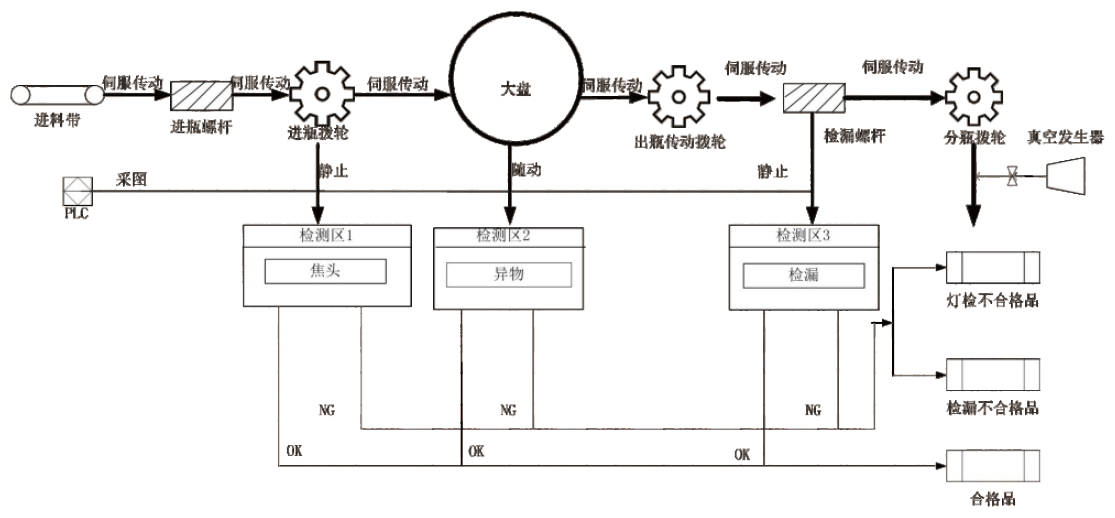

This machine uses machine vision principles for the detection of visible foreign objects. After high-speed rotation and static stop, the industrial camera continuously takes pictures to acquire images. After computer system analysis, it determines whether the inspected product is qualified; leakage detection uses high-voltage discharge detection principle; and automatically separates qualified and unqualified products.

Process Flow

Items to be inspected → Conveyor belt in bottle → Bottle screw feeding → Bottle wheel sorting → Pressing bottle → Rotating bottle → Braking → Photographing → Image processing and analysis → Bottle wheel transition sorting → Uneven screw feeding → Leak detection → Qualified and unqualified products are separated by bottle wheel.

Main Technical Parameters

Applicable range: 1-20ml ampoule injections; oral liquids, penicillin bottle injections, etc.

Detection items: Visible foreign objects (glass chips, fibers, hair, white patches, white spots, etc.), liquid level, leakage (micro-holes, cracks)

Detection speed: 600 bottles/minute

Detection accuracy: Visible foreign objects, ≥40μm (adjustable); Leakage, ≥0.1μm micro-holes and cracks, etc.

Capacity: 11.5kW

Voltage: 380V, 50Hz

Worktable height: (920±40)mm

Dimensions: 3920mmX 2074mmX2000mm (length × width × height)

Net weight: Approximately 4700kg

Main Features

- The whole machine adopts full servo drive and multiple patented technologies, with completely independent intellectual property rights.

- Visible foreign object detection complies with the common Knapp rules.

- Leak detection can detect ultra-fine micro-holes and cracks that cannot be detected by traditional methods.

- Key components are made with CNC precision machining; main purchased parts use internationally renowned brands, and the equipment runs stably and reliably.

- The bottle rotating servo system and detection device are both set on the panel, effectively preventing damage to the equipment transmission and electrical appliances caused by medicine and cleaning liquid, making maintenance simple.

- All specifications use a quick-loading and unloading method, and the large plate uses servo automatic lifting and lowering, making the replacement of specifications simple and fast.

- Using uneven screw feeding, it can meet the needs of single-machine production and can also be used for linkage when connecting before and after.

- The independently developed high-frequency high-voltage power supply has low energy, short time, and small current loaded on the product, which will not cause secondary damage to the medicine.

- It has fault alarm and fault display functions; it has opening stop, ozone catalysis, and electromagnetic protection functions.

- All detection data can be stored, uploaded, and printed.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Use

Mainly used for the detection of visible foreign objects (including glass chips, fibers, hair, white patches, white spots, etc.), liquid level, and leakage (micro-holes, cracks) in ampoules; also applicable to oral liquids and penicillin bottle injections.

Detection Principle

This machine uses machine vision principles for the detection of visible foreign objects. After high-speed rotation and static stop, the industrial camera continuously takes pictures to acquire images. After computer system analysis, it determines whether the inspected product is qualified; leakage detection uses high-voltage discharge detection principle; and automatically separates qualified and unqualified products.

Process Flow

Items to be inspected → Conveyor belt in bottle → Bottle screw feeding → Bottle wheel sorting → Pressing bottle → Rotating bottle → Braking → Photographing → Image processing and analysis → Bottle wheel transition sorting → Uneven screw feeding → Leak detection → Qualified and unqualified products are separated by bottle wheel.

Main Technical Parameters

Applicable range: 1-20ml ampoule injections; oral liquids, penicillin bottle injections, etc.

Detection items: Visible foreign objects (glass chips, fibers, hair, white patches, white spots, etc.), liquid level, leakage (micro-holes, cracks)

Detection speed: 600 bottles/minute

Detection accuracy: Visible foreign objects, ≥40μm (adjustable); Leakage, ≥0.1μm micro-holes and cracks, etc.

Capacity: 11.5kW

Voltage: 380V, 50Hz

Worktable height: (920±40)mm

Dimensions: 3920mmX 2074mmX2000mm (length × width × height)

Net weight: Approximately 4700kg

Main Features

- The whole machine adopts full servo drive and multiple patented technologies, with completely independent intellectual property rights.

- Visible foreign object detection complies with the common Knapp rules.

- Leak detection can detect ultra-fine micro-holes and cracks that cannot be detected by traditional methods.

- Key components are made with CNC precision machining; main purchased parts use internationally renowned brands, and the equipment runs stably and reliably.

- The bottle rotating servo system and detection device are both set on the panel, effectively preventing damage to the equipment transmission and electrical appliances caused by medicine and cleaning liquid, making maintenance simple.

- All specifications use a quick-loading and unloading method, and the large plate uses servo automatic lifting and lowering, making the replacement of specifications simple and fast.

- Using uneven screw feeding, it can meet the needs of single-machine production and can also be used for linkage when connecting before and after.

- The independently developed high-frequency high-voltage power supply has low energy, short time, and small current loaded on the product, which will not cause secondary damage to the medicine.

- It has fault alarm and fault display functions; it has opening stop, ozone catalysis, and electromagnetic protection functions.

- All detection data can be stored, uploaded, and printed.

Previous Page

Related Products

Inquiry