Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

LPJL80 series plastic ampoule electronic microporous leak detector

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

In-line plastic ampoule electronic micro-hole leak detector

Details

Main Use

This equipment comprehensively detects leaks in rows of plastic ampoules produced by a three-in-one blow-fill-seal production line. It can also detect similar packaged products such as rows of eye drops and rows of oral liquids.

Working Principle

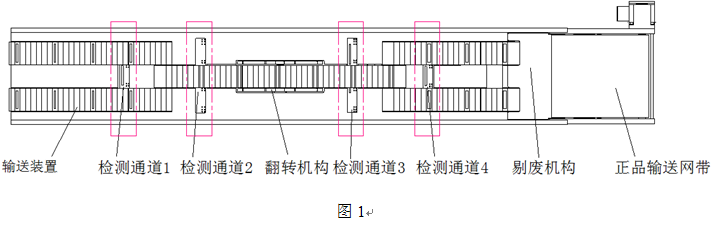

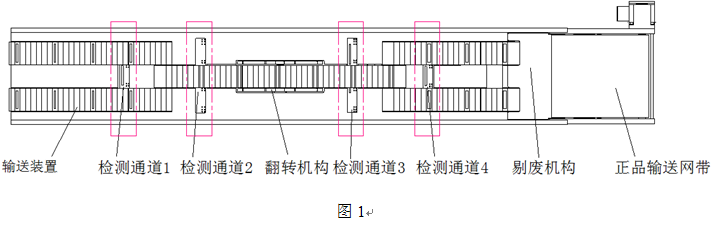

Rows of plastic ampoules are manually or automatically fed onto the infeed conveyor belt. The accelerated conveyor belt separates and sends the ampoules to the inspection station. The conveying device transports the rows of plastic ampoules towards the inspection channel, passing through channels 1 and 2 in sequence. Channels 1 and 2 inspect the body, head, and tail of the rows of plastic ampoules. Then, through a turning wheel mechanism, they are transported to channels 3 and 4 in sequence. Channels 3 and 4 inspect the head, tail, and body of the other side of the rows of plastic ampoules. Finally, the reject mechanism separates the qualified and unqualified products. Qualified products are transported to the subsequent workstations via the qualified product conveyor belt, while unqualified products are collected in a waste bin (the waste bin is provided by the user and is not shown in Figure 1).

Detection Principle

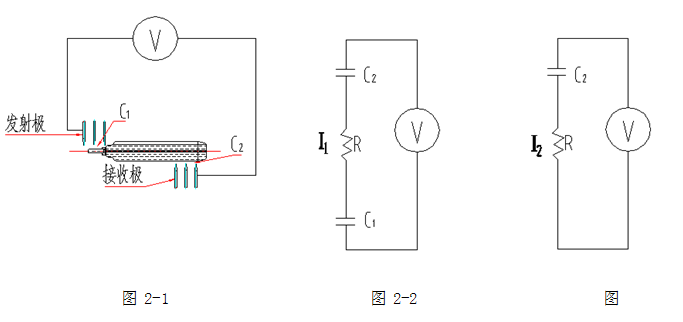

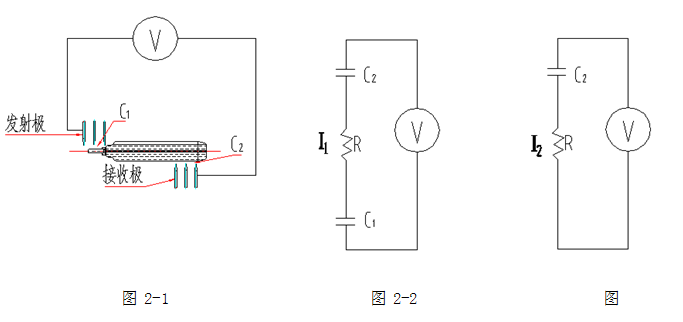

The detection principle is shown in Figure 2-1. In the figure, V is a high-frequency high-voltage power supply, with its two ends connected to the emitter and receiver respectively. C1 and C2 are the capacitances between the emitter and receiver and the solution (due to the container wall separating the solution and the electrodes, there is no direct contact, hence the capacitance). R is the resistance of the solution.

When the row of plastic ampoules is not leaking, the simplified circuit of the entire loop is shown in Figure 2-2. In this case, the circuit will generate a microcurrent I1.

When the row of plastic ampoules leaks, the electrode and the solution will be directly connected, and the capacitance generated by the container wall will disappear. The simplified circuit of the entire loop is shown in Figure 2-3. In this case, the circuit will generate a current I2.

By comparing the magnitudes of I1 and I2, it is possible to determine whether the row of plastic ampoules has a leak.

Main Technical Parameters

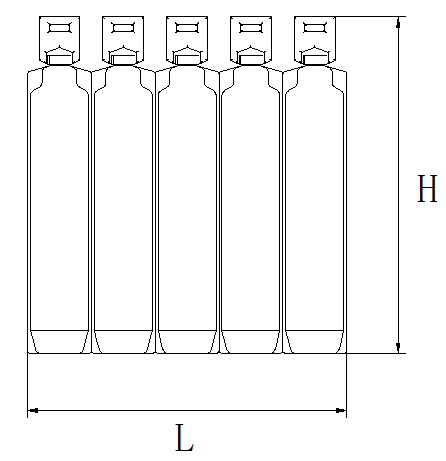

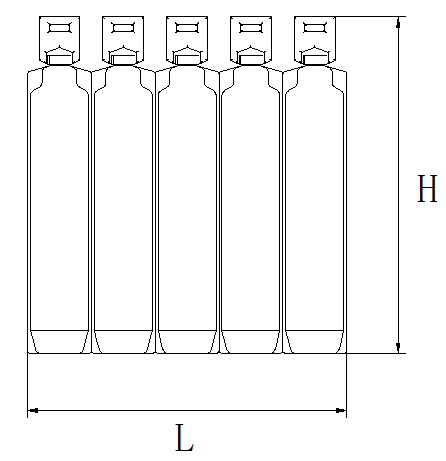

Applicable specifications: Height of rows of plastic ampoules 65≤H≤120mm; Length L≤220mm; (Can be customized according to customer samples)

Output: 0~80 rows/minute

Power: 3kW, 380V 50Hz

Number of detection channels: Multiple sets, customizable

High-frequency high-voltage power supply voltage: 0~30kV adjustable

Dimensions (Length × Width × Height): 2800mm × 935mm × 1650mm

Weight: Approximately 1200kg

Main Features

- Zero pollution. Because no dye or other liquids are used, there is no secondary pollution of the drug.

- High precision. It can detect micro-holes of micrometers and above, which is more precise than traditional vacuum and dyeing detection methods.

- Full inspection. Fully automatic, fully online inspection of each row of drugs.

- Comprehensive detection. Using a patented technology turning structure, the rows of plastic ampoules are turned over, allowing the emitter to detect the upper and lower sides of the head, body, and tail of the rows of plastic ampoules for comprehensive and thorough detection.

- High safety. The energy acting on the rows of plastic ampoules is low and has no side effects on the drugs.

- Customized design. The detection electrodes are arranged according to customer samples to achieve the best detection effect.

- Advanced control. A user-friendly human-machine interface is designed with powerful data acquisition, storage, and control capabilities.

- It has completely independent intellectual property rights and has obtained multiple invention and utility model patents.

- Fully automatic bottle feeding structure can be customized according to customer needs (optional).

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Use

This equipment comprehensively detects leaks in rows of plastic ampoules produced by a three-in-one blow-fill-seal production line. It can also detect similar packaged products such as rows of eye drops and rows of oral liquids.

Working Principle

Rows of plastic ampoules are manually or automatically fed onto the infeed conveyor belt. The accelerated conveyor belt separates and sends the ampoules to the inspection station. The conveying device transports the rows of plastic ampoules towards the inspection channel, passing through channels 1 and 2 in sequence. Channels 1 and 2 inspect the body, head, and tail of the rows of plastic ampoules. Then, through a turning wheel mechanism, they are transported to channels 3 and 4 in sequence. Channels 3 and 4 inspect the head, tail, and body of the other side of the rows of plastic ampoules. Finally, the reject mechanism separates the qualified and unqualified products. Qualified products are transported to the subsequent workstations via the qualified product conveyor belt, while unqualified products are collected in a waste bin (the waste bin is provided by the user and is not shown in Figure 1).

Detection Principle

The detection principle is shown in Figure 2-1. In the figure, V is a high-frequency high-voltage power supply, with its two ends connected to the emitter and receiver respectively. C1 and C2 are the capacitances between the emitter and receiver and the solution (due to the container wall separating the solution and the electrodes, there is no direct contact, hence the capacitance). R is the resistance of the solution.

When the row of plastic ampoules is not leaking, the simplified circuit of the entire loop is shown in Figure 2-2. In this case, the circuit will generate a microcurrent I1.

When the row of plastic ampoules leaks, the electrode and the solution will be directly connected, and the capacitance generated by the container wall will disappear. The simplified circuit of the entire loop is shown in Figure 2-3. In this case, the circuit will generate a current I2.

By comparing the magnitudes of I1 and I2, it is possible to determine whether the row of plastic ampoules has a leak.

Main Technical Parameters

Applicable specifications: Height of rows of plastic ampoules 65≤H≤120mm; Length L≤220mm; (Can be customized according to customer samples)

Output: 0~80 rows/minute

Power: 3kW, 380V 50Hz

Number of detection channels: Multiple sets, customizable

High-frequency high-voltage power supply voltage: 0~30kV adjustable

Dimensions (Length × Width × Height): 2800mm × 935mm × 1650mm

Weight: Approximately 1200kg

Main Features

- Zero pollution. Because no dye or other liquids are used, there is no secondary pollution of the drug.

- High precision. It can detect micro-holes of micrometers and above, which is more precise than traditional vacuum and dyeing detection methods.

- Full inspection. Fully automatic, fully online inspection of each row of drugs.

- Comprehensive detection. Using a patented technology turning structure, the rows of plastic ampoules are turned over, allowing the emitter to detect the upper and lower sides of the head, body, and tail of the rows of plastic ampoules for comprehensive and thorough detection.

- High safety. The energy acting on the rows of plastic ampoules is low and has no side effects on the drugs.

- Customized design. The detection electrodes are arranged according to customer samples to achieve the best detection effect.

- Advanced control. A user-friendly human-machine interface is designed with powerful data acquisition, storage, and control capabilities.

- It has completely independent intellectual property rights and has obtained multiple invention and utility model patents.

- Fully automatic bottle feeding structure can be customized according to customer needs (optional).

Previous Page

Previous Page

Related Products

Inquiry