Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

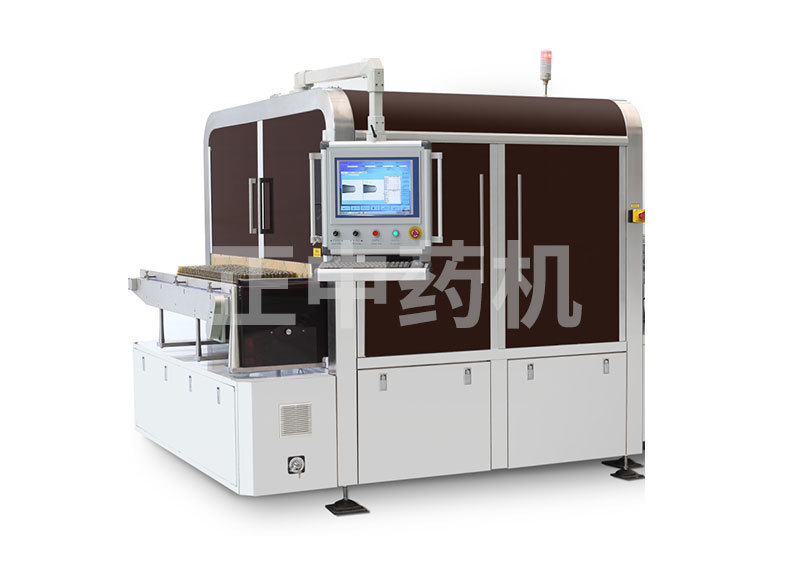

JYP/300 Baijiu Automatic Foreign Object Inspection Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Automatic foreign object inspection machine for liquor

Details

Equipment Overview and Operating Principle

The equipment is primarily used for detecting foreign objects inside alcoholic beverages in the food industry, including residues, glass fragments, hair, and other contaminants within the liquid, as well as inspecting the appearance of bottle caps.

After the preceding process of the product to be inspected is completed, it is conveyed to the bottle-in feed track of the equipment. The bottle-in track then sends the bottles to the in-feed screw, which evenly spaces and feeds the bottles into the bottle-in indexing plate. The indexing plate rotates counterclockwise, transporting the bottles under inspection onto the inspection turntable for thorough testing. Meanwhile, the inspection turntable moves clockwise, with its rotary bottle holders and bottle-holding plungers precisely centering and securing each bottle vertically. Next, the products to be inspected undergo continuous screening at three dedicated stations: one station focuses on visual inspection, while the other two stations are equipped for foreign-object detection. During the foreign-object detection phase, each bottle rapidly spins, brakes, and finally comes to a complete stop—all while high-speed cameras continuously capture images for analysis and processing. Once the inspection is finished, the bottles reach the handover point between the inspection turntable and the bottle-out indexing plate. At this moment, the bottle-holding plungers rise, allowing the bottles to smoothly transition onto the bottle-out indexing plate, which then rotates counterclockwise to deliver the bottles to the rejection mechanism. Here, non-conforming products are automatically routed into the defective-item channel, while conforming items proceed directly into the good-product channel. Thus, the entire inspection process is fully completed.

Main Uses

The equipment is suitable for 50ml to 500ml wine bottles and is designed to detect visible foreign objects inside alcoholic beverages as well as defects in the cap appearance. Specific details include:

1) Foreign objects such as color spots, black dots, white spots, hairs, fibers, glass shards, insects, paper scraps, and more.

2) Cover defects such as missing lids, damage, uneven edges, curled rims, mismatched lid heights, abnormal patterns, and color spots caused by pressing.

3) Abnormal solvent volume.

Main Technical Parameters

Speed: 0–300 bottles/min; Detection accuracy: 60 μm.

Adaptation range: 50–500 mL wine bottles, with dry and clean outer bottle surfaces.

Voltage: 380V 50Hz.

Capacitance: 16.5 kW.

Working height: 950 mm (adjustable).

External dimensions: 5095 × 2500 × 2195 (length × width × height).

Net weight: Approximately 4,500 kg.

Key Features

- The equipment features a compact design, an attractive appearance, and smooth operation.

- Utilizing servo motors from internationally renowned brands ensures precise control of the equipment.

- The equipment is equipped with torque sensors at all transmission points, effectively preventing bottle jams.

- Equipped with high-resolution, high-speed cameras imported from Germany, ensuring stable and reliable detection.

- The equipment features floating foreign object detection, capable of identifying objects visibly floating on the liquid surface. Customers can optionally equip a more advanced floating object detection station based on their specific needs.

- The device features AI learning capabilities.

- Bottle cap detection uses 360-degree, blind-spot-free imaging, enabling comprehensive inspection from all angles.

- Using a servo motor to rotate the bottles allows for effective adjustment of the rotation speed, tailored specifically to different types of foreign objects.

- Sensing devices are installed on the in-feed and out-feed bottle tracks, enabling a bottle-blocking-to-stop-machine function.

- The equipment boasts high safety performance and features an open-door-to-stop function.

- All data feature saving, printing, audit tracking, three-level access control, and fault alarm analysis capabilities.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Equipment Overview and Operating Principle

The equipment is primarily used for detecting foreign objects inside alcoholic beverages in the food industry, including residues, glass fragments, hair, and other contaminants within the liquid, as well as inspecting the appearance of bottle caps.

After the preceding process of the product to be inspected is completed, it is conveyed to the bottle-in feed track of the equipment. The bottle-in track then sends the bottles to the in-feed screw, which evenly spaces and feeds the bottles into the bottle-in indexing plate. The indexing plate rotates counterclockwise, transporting the bottles under inspection onto the inspection turntable for thorough testing. Meanwhile, the inspection turntable moves clockwise, with its rotary bottle holders and bottle-holding plungers precisely centering and securing each bottle vertically. Next, the products to be inspected undergo continuous screening at three dedicated stations: one station focuses on visual inspection, while the other two stations are equipped for foreign-object detection. During the foreign-object detection phase, each bottle rapidly spins, brakes, and finally comes to a complete stop—all while high-speed cameras continuously capture images for analysis and processing. Once the inspection is finished, the bottles reach the handover point between the inspection turntable and the bottle-out indexing plate. At this moment, the bottle-holding plungers rise, allowing the bottles to smoothly transition onto the bottle-out indexing plate, which then rotates counterclockwise to deliver the bottles to the rejection mechanism. Here, non-conforming products are automatically routed into the defective-item channel, while conforming items proceed directly into the good-product channel. Thus, the entire inspection process is fully completed.

Main Uses

The equipment is suitable for 50ml to 500ml wine bottles and is designed to detect visible foreign objects inside alcoholic beverages as well as defects in the cap appearance. Specific details include:

1) Foreign objects such as color spots, black dots, white spots, hairs, fibers, glass shards, insects, paper scraps, and more.

2) Cover defects such as missing lids, damage, uneven edges, curled rims, mismatched lid heights, abnormal patterns, and color spots caused by pressing.

3) Abnormal solvent volume.

Main Technical Parameters

Speed: 0–300 bottles/min; Detection accuracy: 60 μm.

Adaptation range: 50–500 mL wine bottles, with dry and clean outer bottle surfaces.

Voltage: 380V 50Hz.

Capacitance: 16.5 kW.

Working height: 950 mm (adjustable).

External dimensions: 5095 × 2500 × 2195 (length × width × height).

Net weight: Approximately 4,500 kg.

Key Features

- The equipment features a compact design, an attractive appearance, and smooth operation.

- Utilizing servo motors from internationally renowned brands ensures precise control of the equipment.

- The equipment is equipped with torque sensors at all transmission points, effectively preventing bottle jams.

- Equipped with high-resolution, high-speed cameras imported from Germany, ensuring stable and reliable detection.

- The equipment features floating foreign object detection, capable of identifying objects visibly floating on the liquid surface. Customers can optionally equip a more advanced floating object detection station based on their specific needs.

- The device features AI learning capabilities.

- Bottle cap detection uses 360-degree, blind-spot-free imaging, enabling comprehensive inspection from all angles.

- Using a servo motor to rotate the bottles allows for effective adjustment of the rotation speed, tailored specifically to different types of foreign objects.

- Sensing devices are installed on the in-feed and out-feed bottle tracks, enabling a bottle-blocking-to-stop-machine function.

- The equipment boasts high safety performance and features an open-door-to-stop function.

- All data feature saving, printing, audit tracking, three-level access control, and fault alarm analysis capabilities.

Related Products

Inquiry