Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

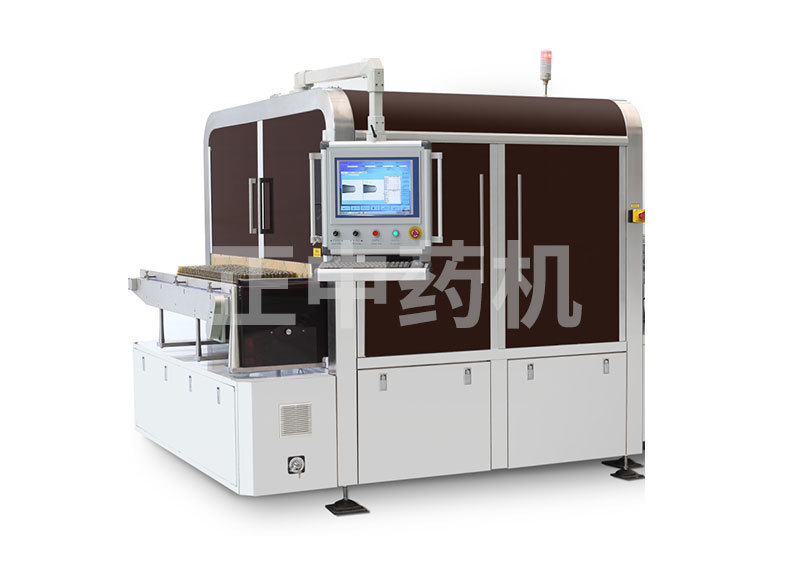

JLKP250 Alcohol Bottle Micro-Crack Detection Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Wine bottle micro-crack detection machine

Details

Main Uses

The JLKP250 alcohol beverage empty bottle micro-crack detection equipment is primarily used for sealing integrity testing of alcoholic beverage containers and can accommodate bottles of various volumes. Positioned before the bottle washing and filling processes, this equipment detects and identifies potential defects such as micro-cracks and micro-holes in the containers, preventing contents from leaking, microorganisms from entering, and other quality-impacting substances from contaminating the bottles. Adding the micro-crack detection step for empty alcohol bottles is crucial for ensuring both the safety and quality of alcoholic beverages.

How it works

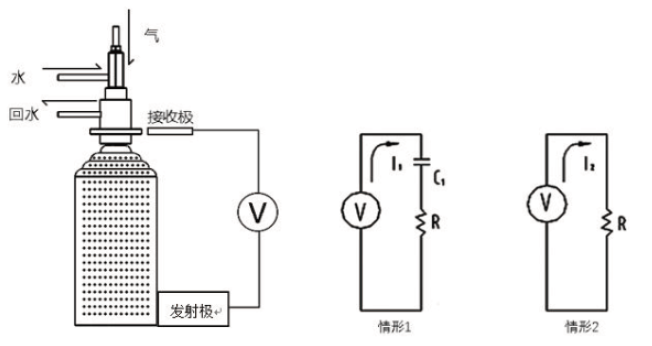

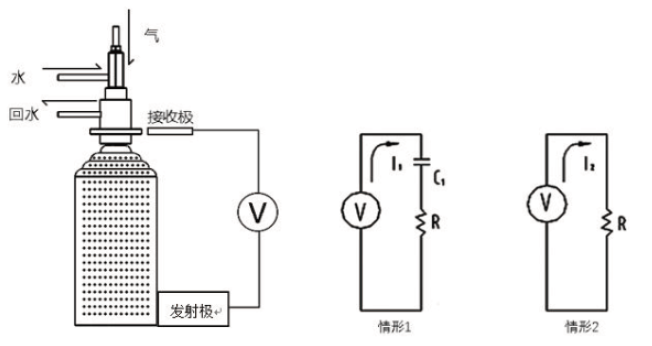

The device operates on the principle of high-voltage discharge detection. Discharge electrodes are arranged in an alternating pattern on the exterior of the container, while the receiving electrodes are positioned at the inner cavity’s bottle opening. A high-voltage detection power supply is connected to the circuit. Before testing, the container’s internal cavity is filled with a conductive medium—water vapor. During detection, the high voltage is activated, and the system monitors and records the leakage voltage values in the electrical circuit. If the leakage voltage exceeds or equals the preset threshold, the product is automatically classified as defective. Conversely, if the leakage voltage remains below the set threshold, the product is deemed acceptable. Finally, once the inspection is complete, the product is conveyed via the PLC control system to the appropriate channel, thereby completing the entire detection process.

Illustration: V represents a high-frequency, high-voltage power supply, with its two terminals connected to the emitter and receiver electrodes, respectively. C1 is the capacitance value between the detection electrode and the conductive medium (since the bottle wall acts as an insulating barrier, preventing direct contact between the electrode and the liquid, this capacitance is formed). R denotes the resistance of the conductive medium.

Situation 1: When the container is intact, a current I1 = v/(R + XC1) flows in the circuit;

Scenario 2: When the container has microcracks, the detection electrode directly connects with the medium, causing the capacitance to disappear and generating a current I₂ = v/R in the circuit.

Clearly, I₂ > I₁; by comparing the current values in the circuit (i.e., the leakage voltage values), we can determine whether the tested product has microcracks—or, in other words, if it’s a defective item.

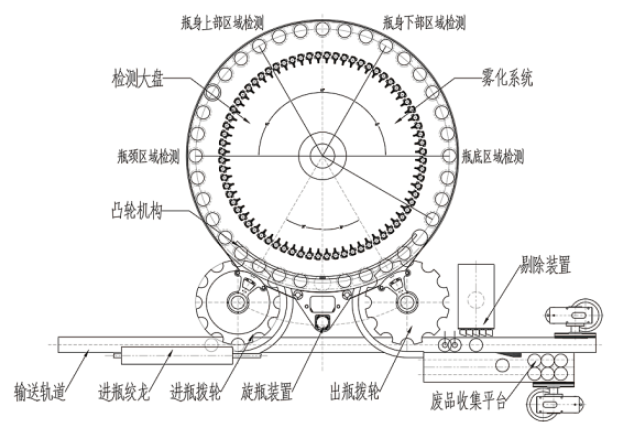

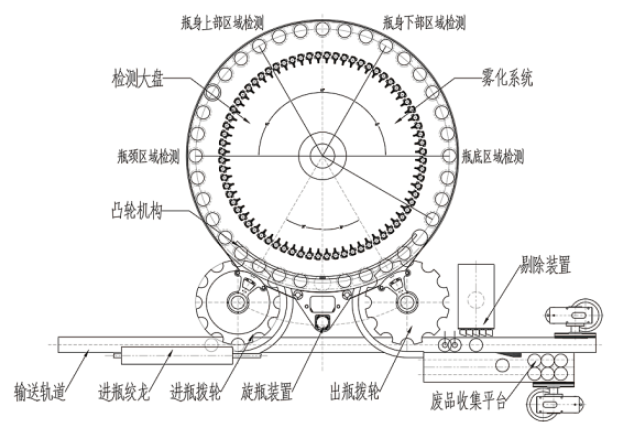

Work Flow

The conveyor track connects to the upstream process, transporting empty wine bottles awaiting inspection to the bottle-feeding screw conveyor. The screw conveyor then neatly arranges the continuously aligned bottles and feeds them into the bottle-feeding indexing wheel. This wheel subsequently transfers the bottles onto the inspection turntable, where a bottom-support-and-top-pressure centering mechanism is employed. Before inspection begins, the inner cavity of each container is filled with a conductive medium. As the containers rotate during inspection, they pass through multiple inspection stations arranged in an alternating pattern, enabling comprehensive, full-coverage detection. Once inspection is complete, the qualified bottles are handed over to the bottle-discharging indexing wheel, from which good products are conveyed via the discharge conveyor belt to the next processing step. Meanwhile, defective bottles are directed by the reject mechanism toward the waste collection platform, thus completing the entire inspection process.

Main Technical Parameters

Adaptation range: 100–1000 ml empty liquor bottles.

Detection accuracy: ≥0.2 μm.

Detection speed: ≤250 Pcs/min.

Detection areas: bottleneck, bottle body, bottle bottom, and other such areas.

High-voltage adjustment range: 0–30 kV.

Capacitance: 7 kW, 380 V, 50 Hz.

Testing station: 4.

Equipment operating height: (960 ± 30) mm.

Equipment dimensions: 2480mm x 2800mm x 2400mm (length x width x height).

Equipment net weight: 5,500 kg.

Key Features

- It is the sealing integrity testing method recommended by USP <1207> in the pharmaceutical industry.

- Employing independently developed high-voltage testing technology with fully owned intellectual property rights.

- Widely applicable, meeting the micro-crack detection needs for 100–1000 ml empty liquor bottles.

- High detection accuracy, fast speed, and excellent repeatability.

- Equipped with a complete set of servo motion control systems, ensuring stable operation.

- All adjustment components utilize a digital mode.

- The equipment is equipped with an ozone catalytic system and electromagnetic radiation-proof film.

- Multiple safety protections, including continuous defect alarms and high-limit discharge suspension protection.

- Stores detection data, operation records, alarm records, and process parameters with full traceability, meeting GMP requirements.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

The JLKP250 alcohol beverage empty bottle micro-crack detection equipment is primarily used for sealing integrity testing of alcoholic beverage containers and can accommodate bottles of various volumes. Positioned before the bottle washing and filling processes, this equipment detects and identifies potential defects such as micro-cracks and micro-holes in the containers, preventing contents from leaking, microorganisms from entering, and other quality-impacting substances from contaminating the bottles. Adding the micro-crack detection step for empty alcohol bottles is crucial for ensuring both the safety and quality of alcoholic beverages.

How it works

The device operates on the principle of high-voltage discharge detection. Discharge electrodes are arranged in an alternating pattern on the exterior of the container, while the receiving electrodes are positioned at the inner cavity’s bottle opening. A high-voltage detection power supply is connected to the circuit. Before testing, the container’s internal cavity is filled with a conductive medium—water vapor. During detection, the high voltage is activated, and the system monitors and records the leakage voltage values in the electrical circuit. If the leakage voltage exceeds or equals the preset threshold, the product is automatically classified as defective. Conversely, if the leakage voltage remains below the set threshold, the product is deemed acceptable. Finally, once the inspection is complete, the product is conveyed via the PLC control system to the appropriate channel, thereby completing the entire detection process.

Illustration: V represents a high-frequency, high-voltage power supply, with its two terminals connected to the emitter and receiver electrodes, respectively. C1 is the capacitance value between the detection electrode and the conductive medium (since the bottle wall acts as an insulating barrier, preventing direct contact between the electrode and the liquid, this capacitance is formed). R denotes the resistance of the conductive medium.

Situation 1: When the container is intact, a current I1 = v/(R + XC1) flows in the circuit;

Scenario 2: When the container has microcracks, the detection electrode directly connects with the medium, causing the capacitance to disappear and generating a current I₂ = v/R in the circuit.

Clearly, I₂ > I₁; by comparing the current values in the circuit (i.e., the leakage voltage values), we can determine whether the tested product has microcracks—or, in other words, if it’s a defective item.

Work Flow

The conveyor track connects to the upstream process, transporting empty wine bottles awaiting inspection to the bottle-feeding screw conveyor. The screw conveyor then neatly arranges the continuously aligned bottles and feeds them into the bottle-feeding indexing wheel. This wheel subsequently transfers the bottles onto the inspection turntable, where a bottom-support-and-top-pressure centering mechanism is employed. Before inspection begins, the inner cavity of each container is filled with a conductive medium. As the containers rotate during inspection, they pass through multiple inspection stations arranged in an alternating pattern, enabling comprehensive, full-coverage detection. Once inspection is complete, the qualified bottles are handed over to the bottle-discharging indexing wheel, from which good products are conveyed via the discharge conveyor belt to the next processing step. Meanwhile, defective bottles are directed by the reject mechanism toward the waste collection platform, thus completing the entire inspection process.

Main Technical Parameters

Adaptation range: 100–1000 ml empty liquor bottles.

Detection accuracy: ≥0.2 μm.

Detection speed: ≤250 Pcs/min.

Detection areas: bottleneck, bottle body, bottle bottom, and other such areas.

High-voltage adjustment range: 0–30 kV.

Capacitance: 7 kW, 380 V, 50 Hz.

Testing station: 4.

Equipment operating height: (960 ± 30) mm.

Equipment dimensions: 2480mm x 2800mm x 2400mm (length x width x height).

Equipment net weight: 5,500 kg.

Key Features

- It is the sealing integrity testing method recommended by USP <1207> in the pharmaceutical industry.

- Employing independently developed high-voltage testing technology with fully owned intellectual property rights.

- Widely applicable, meeting the micro-crack detection needs for 100–1000 ml empty liquor bottles.

- High detection accuracy, fast speed, and excellent repeatability.

- Equipped with a complete set of servo motion control systems, ensuring stable operation.

- All adjustment components utilize a digital mode.

- The equipment is equipped with an ozone catalytic system and electromagnetic radiation-proof film.

- Multiple safety protections, including continuous defect alarms and high-limit discharge suspension protection.

- Stores detection data, operation records, alarm records, and process parameters with full traceability, meeting GMP requirements.

Related Products

Inquiry