Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

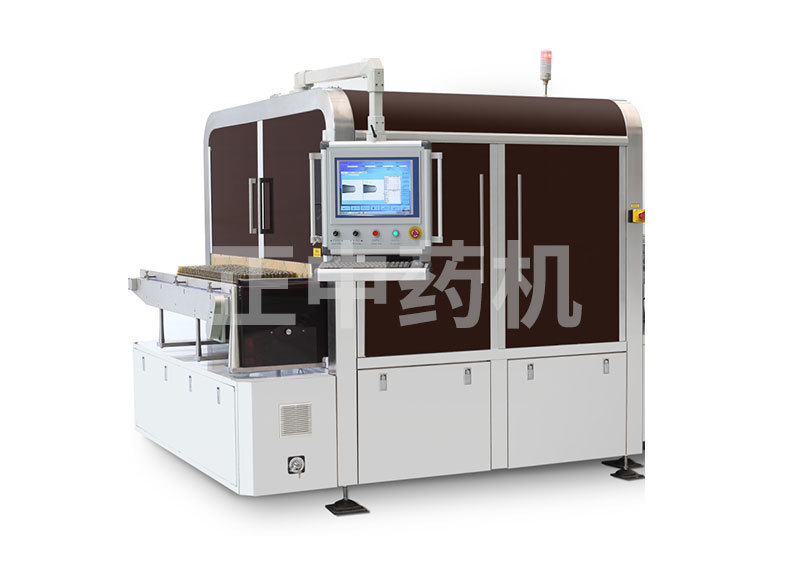

JAJ600/20 Ampoule Injection Vials Automatic Inspection Machine

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Ampoule sealing quality inspection machine

Details

Main Uses

Primarily used for the visual inspection of ampoule injection vials, including detection of defects such as burnt tips, carbonization, black spots, bubble heads, and cracks.

How it works

This machine operates on the principle of machine vision. The ampoules are fed into a screw conveyor via a conveyor belt, and then transferred to an infeed wheel, where they come to a temporary stop relative to the wheel while the designated inspection area is illuminated. An industrial camera continuously captures images of the inspected ampoules, which are subsequently analyzed by an industrial computer to determine whether the ampoules exhibit defects such as burnt tips, carbonization, black spots, bubble heads, or cracks. Finally, after passing through an outfeed wheel and another screw conveyor, any defective ampoules are automatically rejected by a dedicated sorting mechanism.

Main technical parameters:

1. Scope of Application: 1–20 ml Ampule Injections

2. Detection Speed: 1–10 ml, 600 vials/min (adjustable); 20 ml, 400 vials/min (adjustable)

3. Capacitance: 4 kW, 380 (1 ± 5%) V, three-phase AC, 50 Hz.

4. Environmental Adaptability: Temperature range of 10°C to 30°C, with relative humidity between 20% and 70%.

5. Workbench height: 900mm.

6. Overall dimensions: 1930 × 1560 × 1400 (Length × Width × Height).

7. Net Weight: Approximately 1000 kg.

Key Features

1. Novel design, simple structure, smooth operation, and low breakage rate.

2. Replacing standard parts is convenient and quick.

3. Detection accuracy is adjustable, meeting the production requirements of various pharmaceutical products.

4. Can automatically perform the task of rejecting non-conforming products.

5. Test data can be stored and printed, process parameters are traceable, and the system meets GMP requirements.

6. It employs advanced servo systems, photoelectric control, image processing, and industrial control computers, resulting in a high degree of technological integration.

7. The entire machine incorporates multiple patented technologies in its design. (The patented technologies include: A lamp inspection detection device for automated carbonization light testers, Patent No. ZL2020 2 2968515.4; a heating device for detecting burnt tips, Patent No. ZL 2020 2 2729771.8; and a lifting mechanism for tip detection in light testing machines, Patent No. ZL 2018 2 1929287.6.)

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Uses

Primarily used for the visual inspection of ampoule injection vials, including detection of defects such as burnt tips, carbonization, black spots, bubble heads, and cracks.

How it works

This machine operates on the principle of machine vision. The ampoules are fed into a screw conveyor via a conveyor belt, and then transferred to an infeed wheel, where they come to a temporary stop relative to the wheel while the designated inspection area is illuminated. An industrial camera continuously captures images of the inspected ampoules, which are subsequently analyzed by an industrial computer to determine whether the ampoules exhibit defects such as burnt tips, carbonization, black spots, bubble heads, or cracks. Finally, after passing through an outfeed wheel and another screw conveyor, any defective ampoules are automatically rejected by a dedicated sorting mechanism.

Main technical parameters:

1. Scope of Application: 1–20 ml Ampule Injections

2. Detection Speed: 1–10 ml, 600 vials/min (adjustable); 20 ml, 400 vials/min (adjustable)

3. Capacitance: 4 kW, 380 (1 ± 5%) V, three-phase AC, 50 Hz.

4. Environmental Adaptability: Temperature range of 10°C to 30°C, with relative humidity between 20% and 70%.

5. Workbench height: 900mm.

6. Overall dimensions: 1930 × 1560 × 1400 (Length × Width × Height).

7. Net Weight: Approximately 1000 kg.

Key Features

1. Novel design, simple structure, smooth operation, and low breakage rate.

2. Replacing standard parts is convenient and quick.

3. Detection accuracy is adjustable, meeting the production requirements of various pharmaceutical products.

4. Can automatically perform the task of rejecting non-conforming products.

5. Test data can be stored and printed, process parameters are traceable, and the system meets GMP requirements.

6. It employs advanced servo systems, photoelectric control, image processing, and industrial control computers, resulting in a high degree of technological integration.

7. The entire machine incorporates multiple patented technologies in its design. (The patented technologies include: A lamp inspection detection device for automated carbonization light testers, Patent No. ZL2020 2 2968515.4; a heating device for detecting burnt tips, Patent No. ZL 2020 2 2729771.8; and a lifting mechanism for tip detection in light testing machines, Patent No. ZL 2018 2 1929287.6.)

Related Products

Inquiry