Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

ZJL vacuum decay leak detector

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Vacuum decay leak detector

Keyword

Details

Main Use

The vacuum decay leak detector is mainly used for the airtightness detection of solid and liquid sealed packaging. It is suitable for transparent and opaque material packaging containers.

Structural Principle

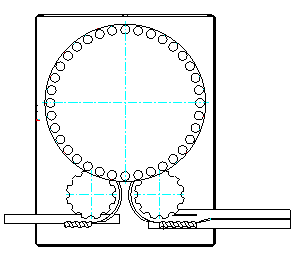

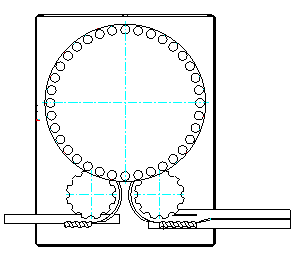

This machine is mainly composed of a bottle feeding mechanism, a turntable inspection area, a bottle output mechanism, a bottle separating mechanism, a frame, and a control operating system.

The packaging container to be tested is sent to the test cavity in the turntable inspection area. After the machine seals the test cavity, a vacuum is drawn. The pressure difference between the inside and outside of the packaging container causes the internal gas to pass through the leak hole into the test cavity. The pressure difference sensor connected to the test cavity monitors the change in pressure, comparing this pressure value with the pressure value of a leak-free packaging container connected to the other end of the pressure difference sensor. The size of the differential pressure sensor value is used to determine whether the packaging container is leaking. Finally, the rejected bottle device automatically distinguishes between qualified and unqualified products.

Workflow

The workflow is summarized as: Packaging container to be tested → Bottle feeding track → Bottle feeding auger → Bottle feeding wheel → Turntable inspection area → Vacuum decay leak detection → Bottle output wheel → Bottle output auger → Bottle separator distinguishes qualified and unqualified products according to computer instructions → Qualified and unqualified products enter the corresponding output tracks respectively.

Technical Parameters:

1. Packaging capacity: 0-500mL;

2. Detection speed: 0-250 bottles/minute;

3. Detection accuracy: ≥10μm;

4. Detection items: Cracks and various micro-hole leaks in the bottle body, bottle shoulder, and bottle bottom;

5. Dimensions: Approximately 3200mm × 2400mm × 2000mm (Length × Width × Height, excluding the length of the bottle input and output tracks);

6. Electric power: 5kw; Voltage: 380V 50Hz;

7. Net weight: 3000kg.

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Use

The vacuum decay leak detector is mainly used for the airtightness detection of solid and liquid sealed packaging. It is suitable for transparent and opaque material packaging containers.

Structural Principle

This machine is mainly composed of a bottle feeding mechanism, a turntable inspection area, a bottle output mechanism, a bottle separating mechanism, a frame, and a control operating system.

The packaging container to be tested is sent to the test cavity in the turntable inspection area. After the machine seals the test cavity, a vacuum is drawn. The pressure difference between the inside and outside of the packaging container causes the internal gas to pass through the leak hole into the test cavity. The pressure difference sensor connected to the test cavity monitors the change in pressure, comparing this pressure value with the pressure value of a leak-free packaging container connected to the other end of the pressure difference sensor. The size of the differential pressure sensor value is used to determine whether the packaging container is leaking. Finally, the rejected bottle device automatically distinguishes between qualified and unqualified products.

Workflow

The workflow is summarized as: Packaging container to be tested → Bottle feeding track → Bottle feeding auger → Bottle feeding wheel → Turntable inspection area → Vacuum decay leak detection → Bottle output wheel → Bottle output auger → Bottle separator distinguishes qualified and unqualified products according to computer instructions → Qualified and unqualified products enter the corresponding output tracks respectively.

Technical Parameters:

1. Packaging capacity: 0-500mL;

2. Detection speed: 0-250 bottles/minute;

3. Detection accuracy: ≥10μm;

4. Detection items: Cracks and various micro-hole leaks in the bottle body, bottle shoulder, and bottle bottom;

5. Dimensions: Approximately 3200mm × 2400mm × 2000mm (Length × Width × Height, excluding the length of the bottle input and output tracks);

6. Electric power: 5kw; Voltage: 380V 50Hz;

7. Net weight: 3000kg.

Previous Page

Next Page

Previous Page

Next Page

Related Products

Inquiry