Product Center

-

● Automatic inspection machine for particulate matter in ampoules

-

● Automatic inspection machine for oral liquid foreign objects

-

● Automatic inspection machine for lyophilized preparations in vials

-

● Automatic foreign object inspection machine for plastic bottle intravenous infusions

-

● Electronic microporous leak detector for ampoule injections

-

● Fully automatic electronic microporous leak detector for infusion

-

● Automatic foreign object inspection machine for glass bottle intravenous infusions

-

● In-line plastic ampoule electronic micro-hole leak detector

RJL3000 Automatic Electronic Microporous Leak Detector for Soft Bags

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Category

Soft bag automatic electronic microporous leak detector

Details

Main Use

Mainly used for leak detection of soft bag intravenous infusions (hereinafter referred to as soft bags). This includes leak detection of defects such as micropores (greater than 0.1μm), bag body sealing, bag mouth welding, and bag tube welding in soft bags.

Working Principle

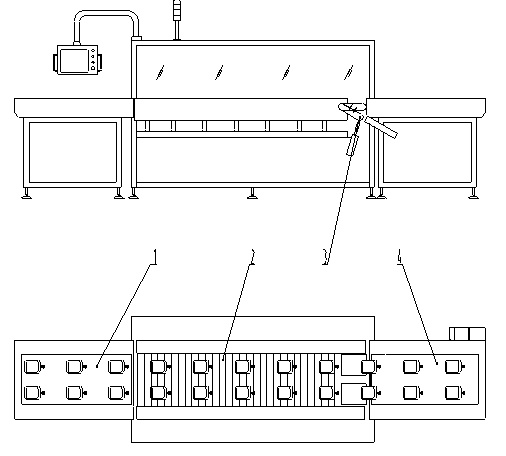

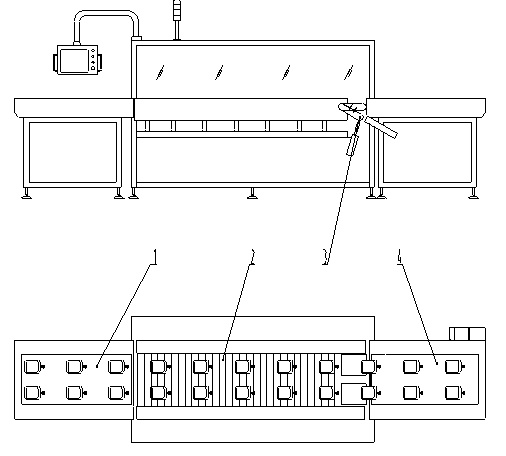

The soft bags to be inspected are transported by a conveyor belt (1) for double-row equal spacing and sent to the inspection channel (2). The inspection channel uses roller conveying and is divided into two inspection areas, front and rear. Each inspection area has four inspection stations. Each inspection station can adjust the inspection position as needed to inspect whether all positions of the soft bag are leaking. Non-conforming products are automatically rejected by the rejection mechanism (3), and conforming products are output from the conveyor belt (4).

Detection Principle

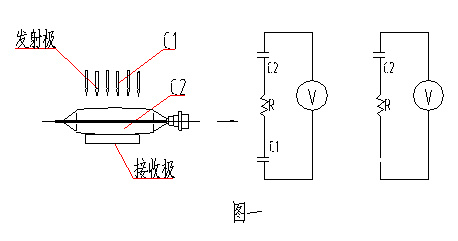

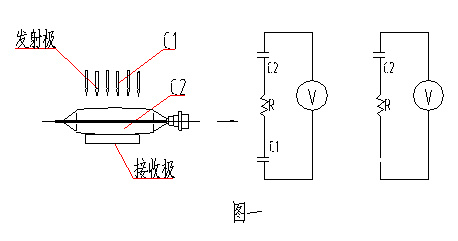

V is a high-frequency high-voltage detection power supply, with both ends connected to the emitter and receiver, respectively. C1 and C2 are the capacitance values between the electrodes and capacitors (due to the isolation of the insulating soft bag film, the electrodes cannot contact the liquid medicine, thus generating capacitance). R is the resistance value of the liquid medicine. When the soft bag does not leak, an induced microcurrent I1 is generated. When the soft bag leaks, the capacitance between the soft bag film and the electrode disappears, the capacitive reactance generated by the capacitance is zero, and a larger microcurrent I2 is generated in the circuit. By comparing the magnitude of the microcurrent, it can be determined whether the soft bag is leaking.

Main Technical Parameters

Output: 2500~3000 bags/hour

Capacitance: 2.6kW, 380V 50HZ

Power Output Range: 10kV~45kV

Frequency Output Range: 500Hz~50kHz

Number of Power Supplies: Multiple high-frequency high-voltage power supplies

Compressed Air: 0.1-1.0MPa

Weight: Approximately 1200kg

Dimensions: 4489×1200×1500mm(L×W×H)

Main Advantages

- No risk of secondary contamination of the drug. Because no liquid such as dye is used, problems such as drug contamination are eliminated.

- Can detect ultra-fine pores and cracks (above 0.1 microns), with leak detection accuracy not possessed by traditional methods.

- Fully automatic, fully online, bag-by-bag leak detection. It can be used as a stand-alone machine or connected to production to form a complete automatic assembly line operation.

- Because the energy loaded on the product is low and the time is short, it has no side effects on the liquid medicine in the product; it realizes non-physical damage inspection of the soft bag.

- One device is suitable for leak detection of soft bags of various different capacities and specifications.

- Special Needs. The key parts of the soft bag can be detected according to the needs of different users.

- The whole machine has a compact structure and beautiful appearance. The user-friendly touch screen interface has powerful control, display, data acquisition, and storage functions.

- The detection voltage and frequency can be adjusted according to different products.

- Provide verification materials and verification schemes

Mainly engaged in the research and development of ceramic new material valves, with metal valves (gate valves, globe valves, ball valves, butterfly valves) as a secondary business. Ceramic valves have been successfully applied in many new energy battery material plants, thermal power plants, nuclear power plants, chemical plants, steel plants, coal chemical industry, polysilicon and other industries, and have been listed as special-purpose products, contributing to energy conservation and environmental protection for enterprises and society.

Main Use

Mainly used for leak detection of soft bag intravenous infusions (hereinafter referred to as soft bags). This includes leak detection of defects such as micropores (greater than 0.1μm), bag body sealing, bag mouth welding, and bag tube welding in soft bags.

Working Principle

The soft bags to be inspected are transported by a conveyor belt (1) for double-row equal spacing and sent to the inspection channel (2). The inspection channel uses roller conveying and is divided into two inspection areas, front and rear. Each inspection area has four inspection stations. Each inspection station can adjust the inspection position as needed to inspect whether all positions of the soft bag are leaking. Non-conforming products are automatically rejected by the rejection mechanism (3), and conforming products are output from the conveyor belt (4).

Detection Principle

V is a high-frequency high-voltage detection power supply, with both ends connected to the emitter and receiver, respectively. C1 and C2 are the capacitance values between the electrodes and capacitors (due to the isolation of the insulating soft bag film, the electrodes cannot contact the liquid medicine, thus generating capacitance). R is the resistance value of the liquid medicine. When the soft bag does not leak, an induced microcurrent I1 is generated. When the soft bag leaks, the capacitance between the soft bag film and the electrode disappears, the capacitive reactance generated by the capacitance is zero, and a larger microcurrent I2 is generated in the circuit. By comparing the magnitude of the microcurrent, it can be determined whether the soft bag is leaking.

Main Technical Parameters

Output: 2500~3000 bags/hour

Capacitance: 2.6kW, 380V 50HZ

Power Output Range: 10kV~45kV

Frequency Output Range: 500Hz~50kHz

Number of Power Supplies: Multiple high-frequency high-voltage power supplies

Compressed Air: 0.1-1.0MPa

Weight: Approximately 1200kg

Dimensions: 4489×1200×1500mm(L×W×H)

Main Advantages

- No risk of secondary contamination of the drug. Because no liquid such as dye is used, problems such as drug contamination are eliminated.

- Can detect ultra-fine pores and cracks (above 0.1 microns), with leak detection accuracy not possessed by traditional methods.

- Fully automatic, fully online, bag-by-bag leak detection. It can be used as a stand-alone machine or connected to production to form a complete automatic assembly line operation.

- Because the energy loaded on the product is low and the time is short, it has no side effects on the liquid medicine in the product; it realizes non-physical damage inspection of the soft bag.

- One device is suitable for leak detection of soft bags of various different capacities and specifications.

- Special Needs. The key parts of the soft bag can be detected according to the needs of different users.

- The whole machine has a compact structure and beautiful appearance. The user-friendly touch screen interface has powerful control, display, data acquisition, and storage functions.

- The detection voltage and frequency can be adjusted according to different products.

- Provide verification materials and verification schemes

Next Page

Next Page

Related Products

Inquiry