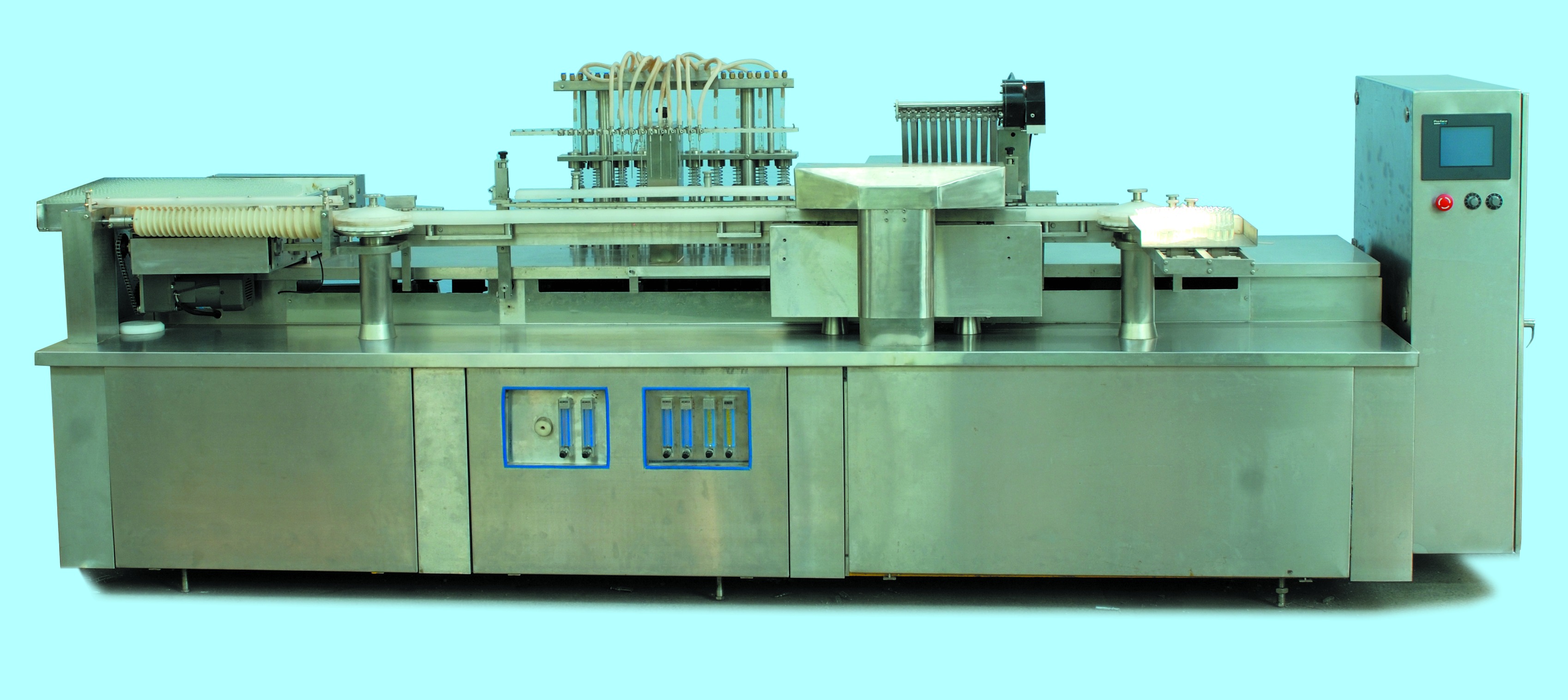

DGF Series Ampoule Filling &Sealing Machine

According to different output demands, three versions like DGF8/1-20 DGF10/1-20 and DGF12/1-10can are provided.

Characteristics:

An integrate star wheel mechanism instead of the traditional sector mechanism for bottle in-feed and out –feed make it convenient for adjustment.

The main transmission of this machine is completed with the synchronal dent form belts, and the walk beam is driven through an imported beeline slide rail

The filling cam completed with specially –designed suck-back function makes no leakage in filling process.

All the bottle support beams are adjusted by buttons, and so easy to be adjusted

Completed with the function of no-bottle-no filling and bottle breakage-no-filling

A special-designed bottle orientating device on filling section ensures the bottle is orientated precisely and reliably, and let the needles plug into the bottle more precisely.

Moving rail for rotating heating of ampoule ensure the ampoule heating uniformity, and the seal beautiful and smooth,

Stainless steel burning nozzles completed with filling machine are suitable to various kinds of liquefied petroleum gas yielded in different place; it is characterized as no corruption, a block and burning sufficiently

Size change parts adopt pin orientation method; the size change parts are orientated precisely, conveniently and quickly

All the transmission cams and the other key parts and components are processed by numerical control millers

Adopt frequency conversion regulating for speed adjustment, the machine is controlled by a PLC. It can be operated both by buttons and a touch screen. All the key electric elements are imported products with well known brand

Specifications:

|

Versions |

DGF 8 / 1 - 2 0 |

DGF10 / 1 - 2 0 |

DGF12 / 1 - 20 |

|

Specs |

1 - 2 0 m 1 |

1 - 2 0 m 1 |

1 - 10m 1 |

|

Output |

8000-22000 pcs / h |

10000-27000 pcs / h |

16000-33000 pcs / h |

|

Water vapor pressure and consumption |

Needle number:8 Gas :2.8-4×1 04Pa、 280L/h Oxygen:2-3×1 05Pa、800~1000L/h |

Needle number:10 Gas:2.8-4×104Pa、 300L/h Oxygen:2-3×105Pa、 1000~1200L/h |

Needle number:12 Gas:3-4×104Pa、 320L/h Oxygen:2-4×105Pa、 1200~1500L/h |

|

Power |

2 kW |

2 kW |

2 kW |

|

Net weight |

About 1500kg |

About 1500kg |

About 1500kg |

|

Overall dimensions |

3847 x1347x1300 mm |

3847x1347x1300 mm |

3847x1347x1500 mm |

DGA Series Ampoule Filling &Sealing Machine

Characteristics:

Take liquefied petroleum gas or urban gas as the fuel

The cam designing take the method combining computer simulation and geometric analyzing, it make the delivery of ampoules among screw, sector and walk bean accurately and results in few bottle breakage, the bottle breakage rate is almost naught

The in-feed screw is made of polyformaldehyde

Moving rail for the rotating heating of ampoule ensures the ampoule heating uniformity, and the seal beautiful and smooth.

Stainless steel burning nozzles completed with filling machine are suitable to various liquefied petroleum gas yielded in different place, it is characterized as no corruption, a block and burning sufficiently.

The transmission principal axis and the bottle rotating transmission axis of filling machine adopt imported high-rigidity chrome plated axes made of the high-chrome bearing steel which is characterized as high intensity, no-distortion and a good corrosion-resistant.

The out-feed device is completed with the macromolecule plastic spring slices characterized as changeable, wearable and high elasticity

Size change parts adopt pin orientation method; the size change parts are orientated precisely, conveniently and quickly

All the transmission cams and the other key parts and components are processed by numerical control millers

Adopt frequency conversion regulating for speed adjustment, the machine is controlled by a PLC. It can be operated both by buttons and a touch screen. All the key electric elements are imported products with well known brands,

Specifications:

|

Version |

DGA 6 / 1 - 2 0 |

DGA8 / 1 - 2 0 |

DGA10 / 1 - 1 0 |

|

Specs |

1 - 2 0 m 1 |

1 - 2 0 m 1 |

1 - 1 0 m 1 |

|

Output |

6000-16000pcs/h |

8000-22000pcs/h |

10000-28000pcs/h |

|

Water vapor pressure and consumption |

Needle number:6 Gas:2.8-4×1 04Pa、 200L/hour Oxygen:2-3×105Pa、 900L/hour |

Needle number:8 Gas:3-4×104Pa、 280L/hour Oxygen:2-4×105Pa、 1200L/hour |

Needle number:10 Gas:3-4×1 04Pa、 350L/hour Oxygen:2-4×105Pa、 1500L/hour |

|

Power |

2 kW |

2 kW |

2 kW |

|

Net weight |

about1500kg |

about1500kg |

about1500kg |

|

Overall dimensions |

2900x1750x1300 mm |

3240x1600x2600 mm |

3240x1600x2600 mm |

CONTACT INFORMATION

OFFICIAL ACCOUNTS